Global Fortune 500 Financial Services Company Reduces Inaccurate Invoices By 94% With Kure

Vicente Monasi

Regional Commercial Performance Manager, Global Financial Services Company

PROJECT SUMMARY

Business Case

Increase sales, increase productivity of the Invoice department, increase customer satisfaction, reduce financial cost

Root Cause Analysis

The need to do it manually

Only one had been trained

Solutions Implemented

Create a system where customers may place directly their orders and avoid mistype errors (from customer and customer representatives)

Train two sales team members to request and upload prices list timely (once a week)

Train two member of the warehouse to request on time the payment for allowing using the bar code system and track the inventory online

Change the invoice and dispatch processes to avoid redundancies

Project Results

The process of invoicing is in control and between the limits required

Customers are not complaining about late or defective invoices

Lost sales had been reduced to zero

The total lead time had been reduced by 40% since the creation of Web Customer Link

The Challenge

In the demanding world of financial services, ensuring accuracy and customer satisfaction is crucial. At this global Fortune 500 financial services company, a challenge arose in the Sales Department: reducing invoice defects. These errors not only wasted time but also led to dissatisfaction among customers. Vicente Monasi recognized the need for change and embarked on a journey to reduce errors by at least 90%.

The Approach

Reducing invoice errors from 64 per month to less than 6 is no small feat. These errors caused disruptions, rework, and unhappy customers. Vicente understood that addressing this challenge required a focused effort and the right tools. With Kure, the AI-driven process improvement workflow, Vicente could optimize the application of his GLSS Lean Six Sigma training.

Central in the training and Kure is the DMAIC process improvement methodology, a 5-step approach of Define, Measure, Analyze, Improve, and Control. Kure, as a knowledgeable mentor, guided Vicente through the DMAIC process improvement methodology, unraveling the mysteries hidden within his process.

Define

With Kure, Vicente charted a course for success. By creating a project charter and employing process mapping and data collection techniques, he gained valuable insights. It became clear that the current process lacked uniformity and was plagued by numerous errors.

Kure guided Vicente in defining the project, setting a measurable goal, and organizing the venture. Kure acted as a friendly coach, providing step-by-step guidance to ensure a clear definition of the problem, the project, and the timeline. To provide clarity and focus, Kure summarizes the improvement effort in a Charter and Project Timeline. Vicente’s goal was to reduce inaccurate invoices from 64 to less than 6 per month.

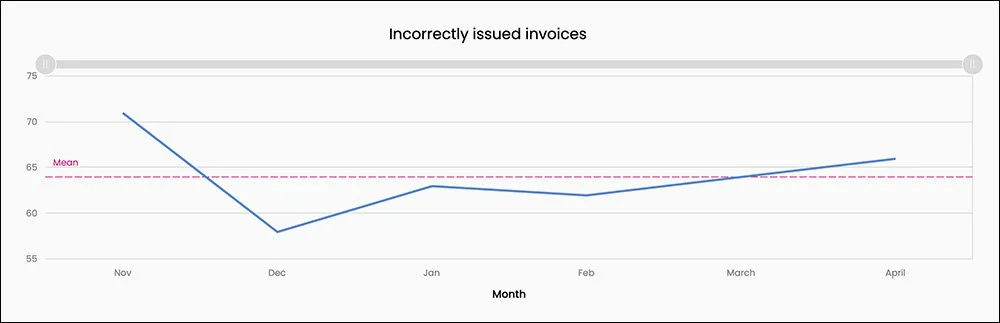

Measure

With Kure’s As-Is Process Map, Vicente gained a deep understanding of the current process and insights into opportunities for improvement. To better understand these opportunities data is needed. Projects often struggle with data collection and analysis. Kure makes it easy by facilitating data collection, then, using this data to conduct Clue Detection analysis. These clues point to the project toward the best opportunities for improvement.

Vicente’s data confirmed the process was averaging 64 inaccurate invoices per month and varied significantly. Digging deeper into the data, he quickly learned there were a variety of errors made throughout the process. Like a lighthouse in the fog, Kure illuminates the way, providing a solid foundation for the Root Cause Analysis.

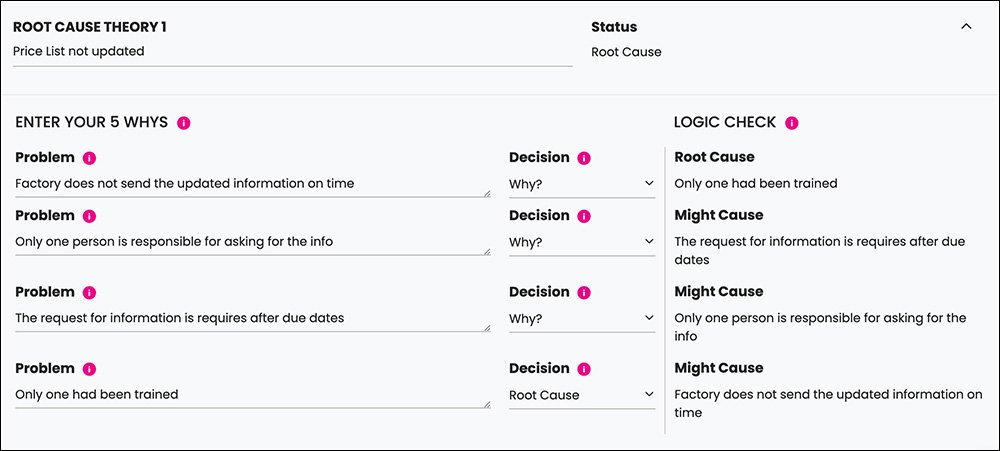

Analyze

Many improvement projects fall into a pitfall when attempting to uncover root causes, often wasting precious time and resources in the pursuit. Guided by Kure, Vicente’s hunt for riches paid off. Using the Fishbone Diagram and the 5 Whys method. The valuable Root Causes unearthed were:

The need to do the work manually

Only one person had been trained

Prices list out of date

Inventory levels are inaccurate

Part serial number errors

Kure's AI analysis and guidance ensured a clear link between the project goals and root causes.

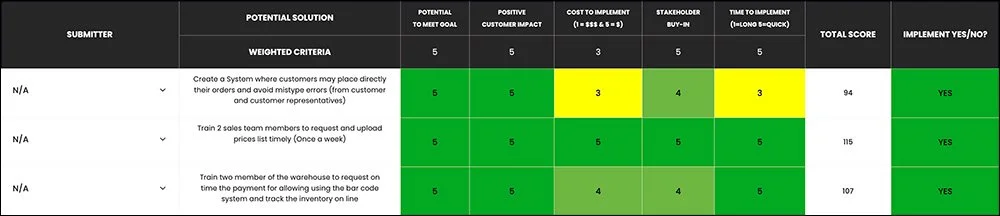

Improve

Effective improvements need to be linked to the root causes; Kure’s automated pathway ensures the root causes discovered are tied to the solutions developed. With Kure’s Solution Selection Matrix, the team collaboratively developed solutions that would provide the most impact for the least effort. The team chose to:

Create a system where customers place orders directly and avoid mistype errors made when customer representatives take orders directly from the customer.

Train sales members to upload the price list timelier, once per week.

Train team members of the warehouse to request on-time payment from the bar code system and track inventory online.

Change the invoice and dispatch process to avoid redundancies.

Kure led the team along a path to collaboratively develop and implement solutions, then guided them through demonstrating results with a Verification of Improvement.

The results spoke volumes. With GLSS Training guiding the way, the project surpassed expectations. Invoice defects plummeted by an astounding 94%, from 64 to just 4 per month, exceeding expectations. Complaints about late or defective invoices disappeared, and lost sales became a thing of the past.

Control

The challenge lies not just in improvement but in sustaining it. Kure, like an automated playbook for success, provides strategic insights and guidance to navigate the issues of closing a project by facilitating the Project Handoff. The handoff effectively passes the baton to daily operations to ensure the results are sustained, Kure’s Monitoring & Response Plan identifies how day-to-day operations can pick up the ball and carry the improved process forward, freeing up Vicente to focus on the next improvement projects. Vicente saved the company $200,000 annually in lost sales, the financial cost of credit notes and reprocessing costs.

Conclusion

Vicente’s success story is a testament to the power created with the use of Kure. When people have all the tools and coaching needed in one intuitive application, it allows them to focus on solving problems, spending no time dealing with tedious training, stressful spreadsheets, and ponderous presentations.

Kure eliminates the uncertainty and complexity of the past, saving time and ensuring a project doesn't stray down the wrong paths. Like an autopilot for process improvement, Kure navigates your project to your goal, using the best route to maximize ROI.