Automotive Manufacturer Reduces Feed Line Cycle Time By 15% With Kure

PROJECT SUMMARY

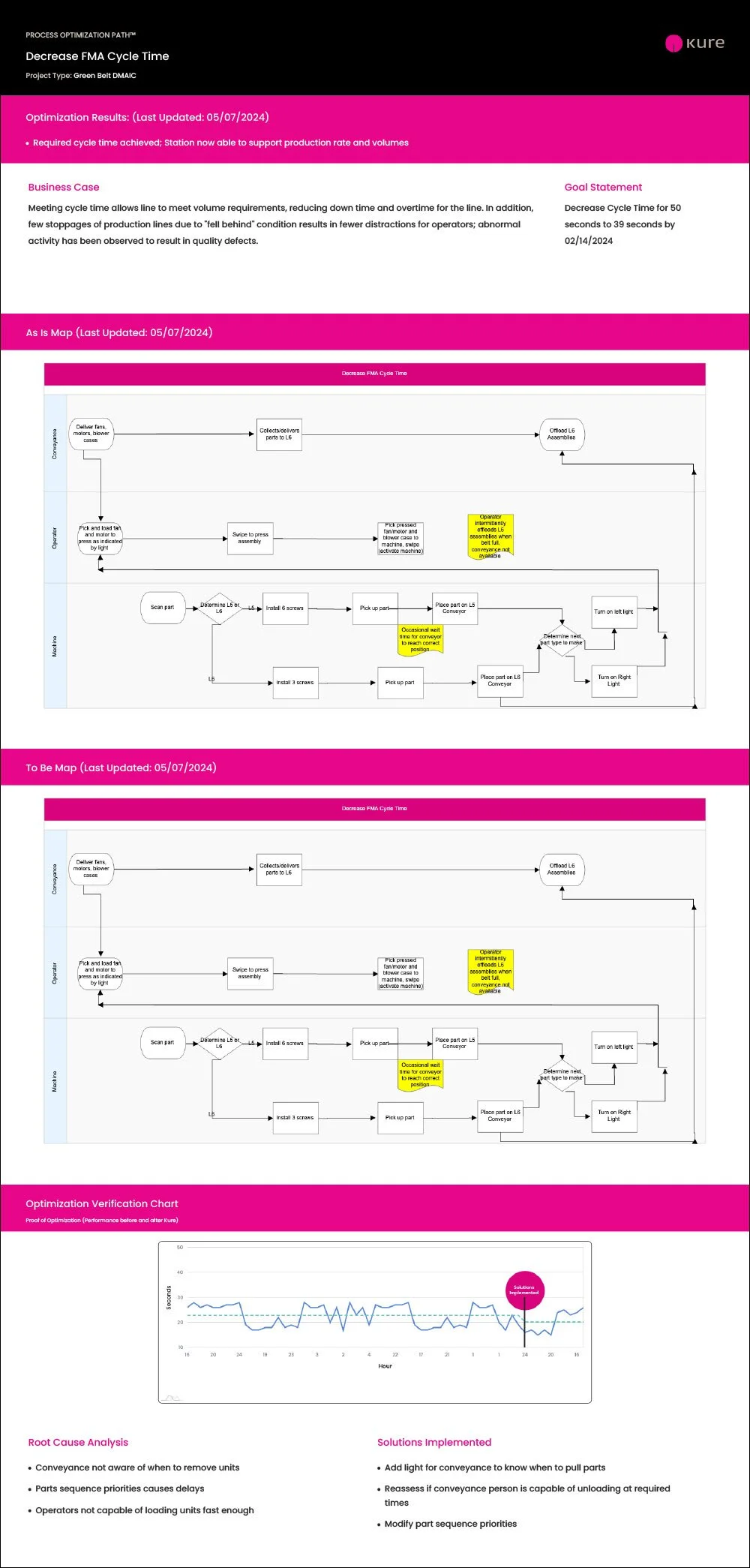

Business Case

Meeting cycle time allows line to meet volume requirements, reducing down time and overtime for the line. In addition, few stoppages of production lines due to “fell behind” condition results in fewer distractions for operations; abnormal activity has been observed to result in quality defects.

Root Cause Analysis

Conveyance is not aware of when to remove units

Parts sequence priorities cause delays

Operators are not capable of loading units fast enough

Solutions Implemented

Add light for conveyance to know when to pull parts

Reassess if conveyance person is capable of unloading at required times

Modify part sequence priorities

Project Results

Feed line cycle time reduced by 15%

The Challenge

In the dynamic world of automotive technology manufacturing, staying ahead means delivering cutting-edge technology rapidly. Even the smallest improvements can be the difference between success and failure. At this leading automotive technology manufacturer faced the challenge of improving production efficiency. The facility was grappling with longer cycle times at a crucial manufacturing station, which impeded its ability to meet growing demands. *Katherine, a Senior Process Engineer, recognized the necessity to enhance operational efficiency without sacrificing quality, prompting her to seek out a solution that could address these issues rapidly.

The Approach

Katherine opted for Kure, the only AI-driven process improvement workflow, to automate the application of her GLSS Lean Six Sigma Training & Certification. Kure guides the project team through the DMAIC process improvement methodology, a 5-step approach of Define, Measure, Analyze, Improve, and Control. With Kure’s guidance, a project avoids the typical delays and detours to arrive at solutions 3X times faster and with better results than the traditional approach.

Define

The initial phase involved clearly defining the problem: the cycle time at a specific station was averaging 23 seconds but needed to be reduced to 20 seconds to align with production demands. This bottleneck was starving to main production lines, leading to delays, increased overtime, and operational inefficiencies.

Kure summarizes the improvement in a Charter and Project Timeline. The goal was to reduce the cycle time from 23 seconds to the needed 20 seconds.

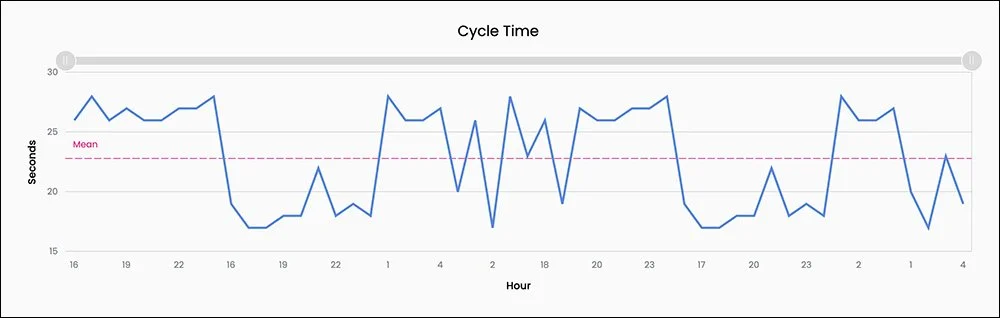

Measure

Using Kure’s As-Is Process Map Katherine gained valuable insights that pointed to opportunities for improvement. She measured process performance, focusing on the cycle times and identifying variability in the operations of the conveyance personnel. This data collection was crucial to establishing a Baseline for making improvements and for providing Clues. Kure’s patent-pending AI analysis of the project’s data detection clues to potential root causes.

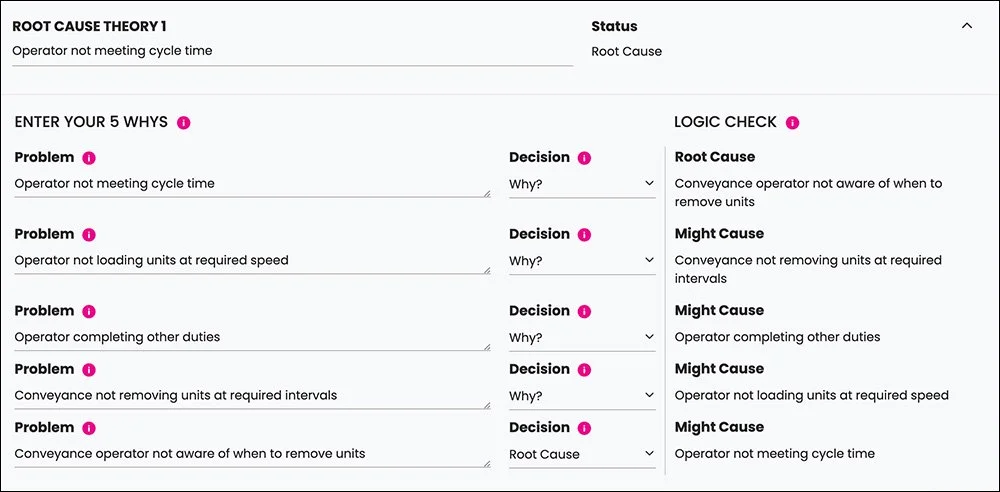

Analyze

Most improvement projects fail to get results because of the inability to understand the root causes. With Kure’s step-by-step approach, Katherine verified the root causes with the use of a Fishbone and the 5 Whys method. The root causes were:

The conveyance operators are not aware of when to remove parts

Part sequence priorities cause delays

Operators not capable of loading units fast enough

Improve

With the root causes identified, the team moved on to the improvement phase. Effective solutions must address the root causes. Kure’s automated workflow enables the team to stay focused on the root causes. With the Solution Selection Matrix within Kure, the team collaborated on developing the solutions that would provide the most impact, these were:

Visual signals for conveyance to know when to pull parts.

Reassess if the conveyance personnel are capable of unloading at the required times.

Optimizing the part sequence.

With these improvements the cycle time was slashed by 15%, hitting the desired target. With the critical stations in sync with the production lines, the volume surged. Overtime was no longer needed to meet demand and the company strengthened its position as a leading provider of automotive technology.

Control

Improving is but half the battle. The performance must be sustainable going forward. Following Kure’s workflow, Katherine implemented controls including regular training sessions for operators and an ongoing Monitoring & Response Plan of the cycle times. With these tactics in place, the people doing the work could easily keep it in control. Kure’s Project Handoff ensured that the operations team had all they needed to be successful.

Conclusion

Katherine’s project illustrates what is possible when problem-solvers have the tools and guidance they need in a collaborative and intuitive application. Kure enables teams to focus on the problem and less on cumbersome software and reports. This case study highlights the effectiveness of Kure in fostering an environment of continuous improvement and operational efficiency in the fast-paced automotive technology sector.

*We value our clients' confidentiality. While we've changed their names, the results are real.