Air Force Medical Support Team Reduced Admin Errors To Under 5% With Kure

PROJECT SUMMARY

Problem: The Line of Duty (LOD) process was overly complex, with too many steps and handoffs—leading to missed details and delays in getting care to injured service members.

Results: The team streamlined the workflow, cutting administrative errors to under 5%.

The Problem

When a service member is injured, they rely on the Line of Duty (LOD) process to receive the benefits and care they deserve. At one Air Force site in Chicago, that process had become a bottleneck. With too many people involved and no clear structure, the system was prone to mistakes and delays—leaving injured members waiting for the care they urgently needed.

It wasn’t just about paperwork; it was about people. Each error or delay added real stress for service members and the staff trying to support them. The team knew things had to change.

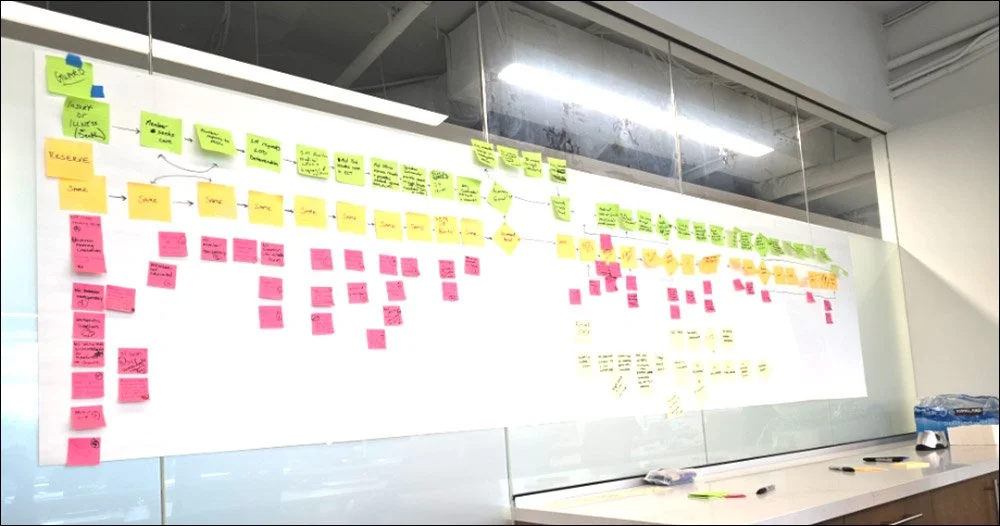

To take on this challenge, a group of professionals—led by a project leader enrolled in Lean Six Sigma Yellow Belt Training—stepped up. They also turned to Kure, an AI-powered process improvement platform that uses the proven DMAIC (Define, Measure, Analyze, Improve, Control) method to guide teams through problem-solving. Kure helped them stay focused, offered step-by-step support, and provided insights using built-in data analysis and expert suggestions.

The team’s goal? Make the process faster and more reliable—without compromising care. And by applying the principles of Ethical Efficiency™, they made sure their improvements were not just effective, but fair and respectful to the people impacted most.

The Root Causes

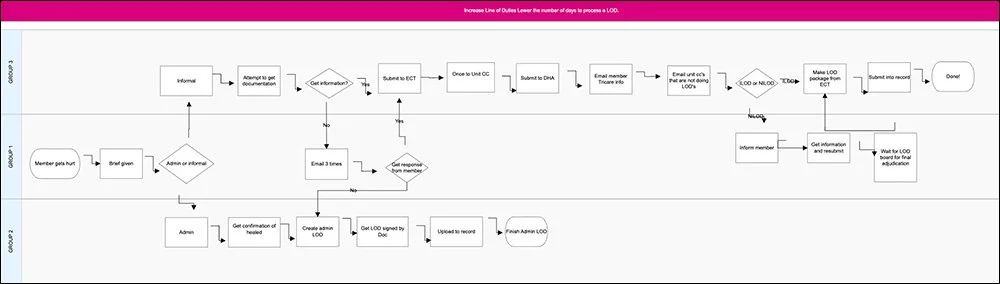

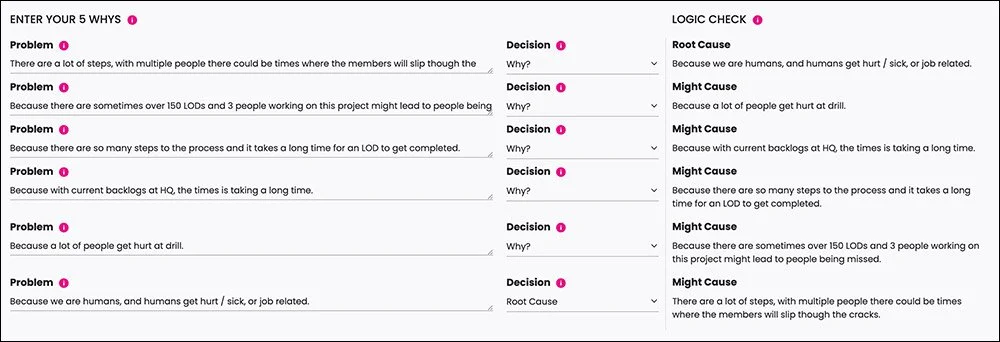

Using Kure’s AI-guided workflow, the team worked through the Define, Measure, Analyze, Improve, and Control (DMAIC) steps to uncover what was really going wrong. They identified three key issues:

The existing LOD tracker was outdated and inaccurate.

Too many handoffs between staff members created confusion and errors.

There was no built-in way to make sure each case was fully followed through.

Not only were these problems slowing things down—they were putting people at risk of falling through the cracks. Guided by Ethical Efficiency, the team stayed focused on creating a better, more humane system. They asked, “How do we build a process that’s accurate and kind? One that protects both performance and people?”

The Solutions

With help from Kure’s smart guidance and data insights, the team made powerful changes:

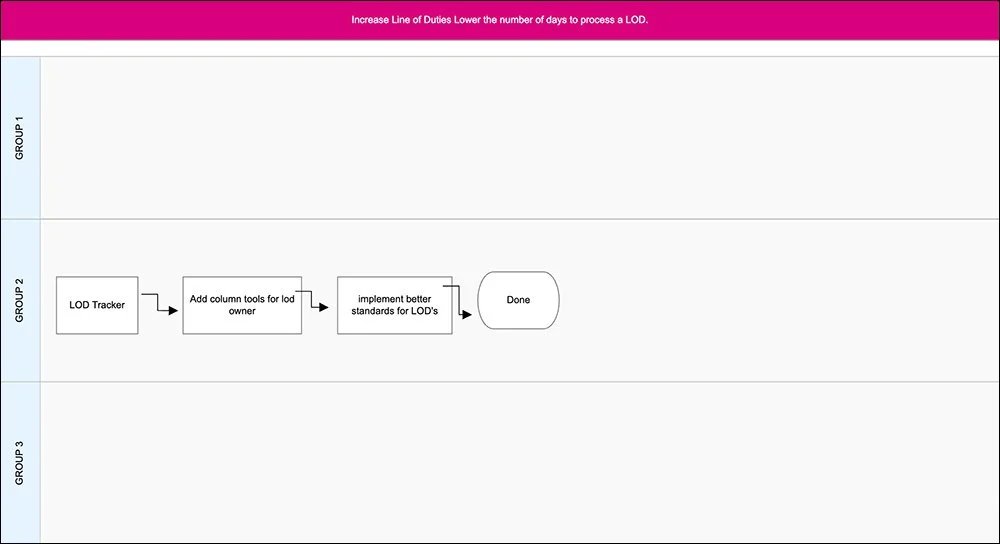

They revamped the LOD tracker, improving accuracy and usability.

They simplified the workflow, reducing the number of people who needed to touch each case.

They added safeguards—like clear checkpoints—to make sure no case slipped through unnoticed.

These improvements made the process faster and more reliable. More importantly, they helped build a system that supported staff and service members alike—balancing operational efficiency with human care.

The Results

The difference was clear: administrative errors dropped to below 5%. That meant fewer delays, faster access to care, and a lot less stress for everyone involved.

This wasn’t just a win for performance—it was a win for people. The project became a shining example of Ethical Efficiency in action: reducing waste, protecting dignity, and doing what’s right while getting great results.

Conclusion

With Kure guiding the way, the Air Force Medical Support team completed their improvement project faster and more confidently than ever. The platform’s AI-driven workflow, real-time suggestions, and built-in data analysis made problem-solving easier and more effective.

By putting people first and leaning into Ethical Efficiency, the team didn’t just fix a broken process—they created a better one. One that’s simpler, faster, and more compassionate. And now, they’re well-positioned to carry those improvements forward, delivering long-term impact for the mission and the military members who count on them.