Greenhouse Increases Packing Productivity By 10% With Kure

PROJECT SUMMARY

A greenhouse business faced a significant challenge in its packing process, particularly with its hydrangeas. Packing these delicate plants was taking far too long, leading to reduced quality, increased labor costs, and unhappy customers.

In an effort to solve these problems, the organization turned to Kure, an AI-driven process improvement software. Kure’s step-by-step guidance, real-time data analysis, and helpful suggestions allowed the team to find solutions more quickly, making their packing process smoother and more efficient.

The Problem

Running a greenhouse comes with many challenges, especially when balancing efficiency with delivering top-quality plants. The team discovered that their hydrangea packing process was slowing down their operations. The labor-intensive task of packing the plants was causing delays, and the team could only pack 63 hydrangeas per hour. This slow pace directly impacted plant quality, pushed up labor costs, and left customers unsatisfied.

The extended time it took to pack each hydrangea exposed the plants to heat stress, damaging their overall quality before they reached customers. Additionally, this inefficiency led to increased labor costs, especially during peak harvesting seasons when more workers were needed. The delays and resulting quality issues were also affecting the company’s reputation, as customers were receiving plants that fell short of their expectations.

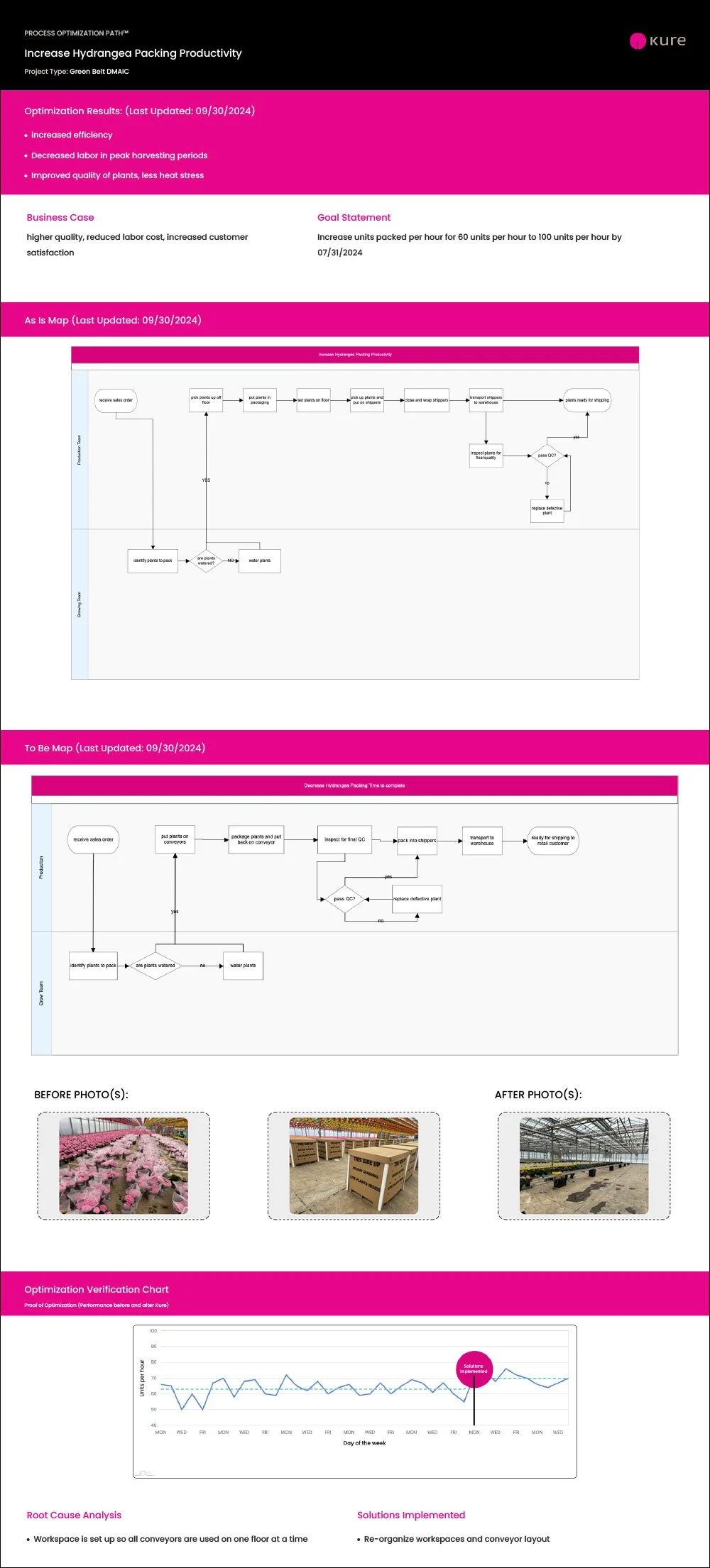

The business knew it had to find a way to fix the packing process to maintain high-quality plants, reduce costs, and keep customers happy. A skilled team of professionals, led by a project leader undergoing Lean Six Sigma Green Belt Training from GLSS, was formed to tackle the problem. They also used Kure to streamline their workflow and focus on problem-solving, using the DMAIC (Define, Measure, Analyze, Improve, Control) approach to guide them through each phase of the project.

The Root Causes

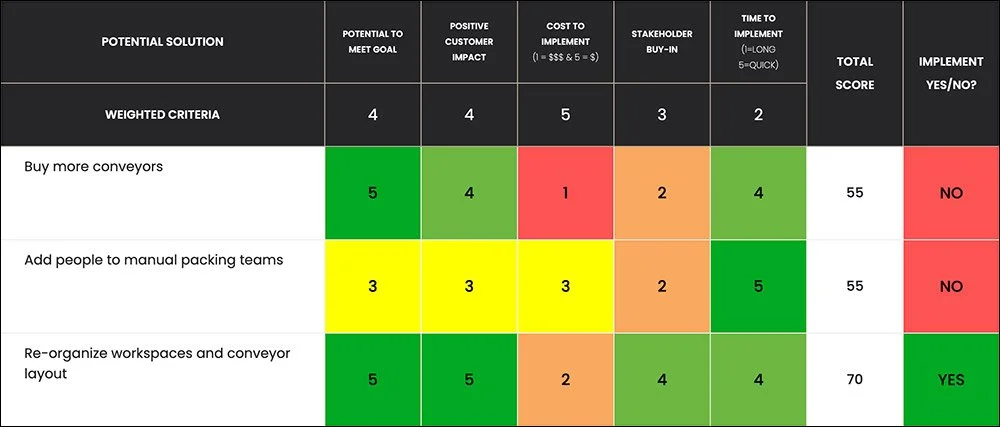

Once the team began analyzing the situation, it became clear that the greenhouse’s workspace layout and conveyor system were the main contributors to the delays. The conveyors were only being used on one floor at a time, forcing workers to move around too much and slowing down the entire process. This inefficient layout made it harder to keep the packing flow steady, especially during busy periods.

The constant back-and-forth movements and poor use of conveyors led to higher costs and lower-quality results. It was clear that a new approach was needed to make the packing process more efficient.

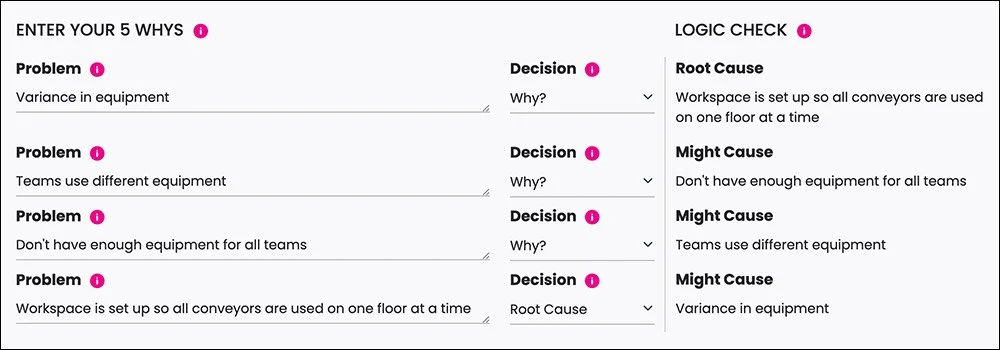

The Solutions

Using Kure’s AI-driven tools, the team was able to zero in on the root causes and find a solution that would make a real difference. Kure’s guidance helped the team restructure the workspace and improve the flow of work. The conveyors were reorganized so they could be used across multiple floors simultaneously, allowing for smoother, more efficient packing.

By minimizing unnecessary movements and optimizing the conveyor layout, the team was able to cut down the time it took to pack each hydrangea. Kure’s AI-driven insights ensured that the changes were not only quick to implement but also highly effective in reducing the bottlenecks in the process.

The Results

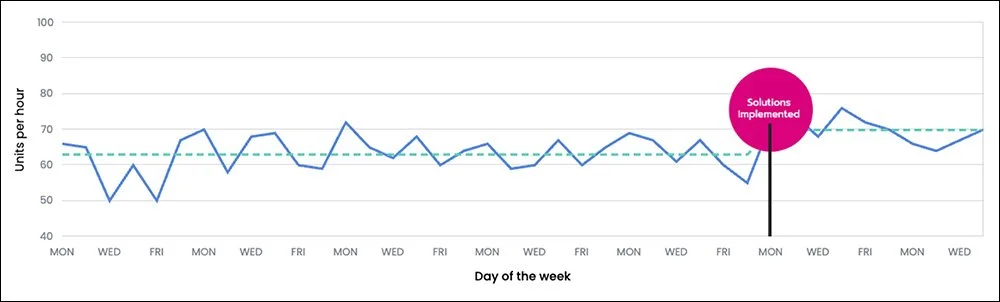

The results were nothing short of impressive. By reorganizing the workspace and optimizing the conveyor system, the greenhouse was able to:

Improve packing productivity by 10%, allowing them to pack and ship hydrangeas faster and reduce the risk of heat stress on the plants.

Lower labor costs during peak harvesting seasons, as fewer workers were needed to manage the same workload.

Increase customer satisfaction, as the faster packing times led to healthier plants being delivered on time, restoring the business’s reputation for high-quality products.

Conclusion

Kure’s AI-powered process improvement software played a key role in transforming the greenhouse’s operations. The platform’s innovative approach, with its helpful suggestions, AI-driven analysis, and efficient project guidance, allowed the team to achieve quicker results and streamline their workflow.

By redesigning its packing system with Kure’s support, the greenhouse was able to solve long-standing issues, boost productivity, and improve the quality of its plants. This successful project has positioned the business for long-term growth, giving them the tools and confidence to continue optimizing their processes and delivering exceptional products to their customers.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.