Luminara & Company Decreased Candle Production Time By 34% With Kure

PROJECT SUMMARY

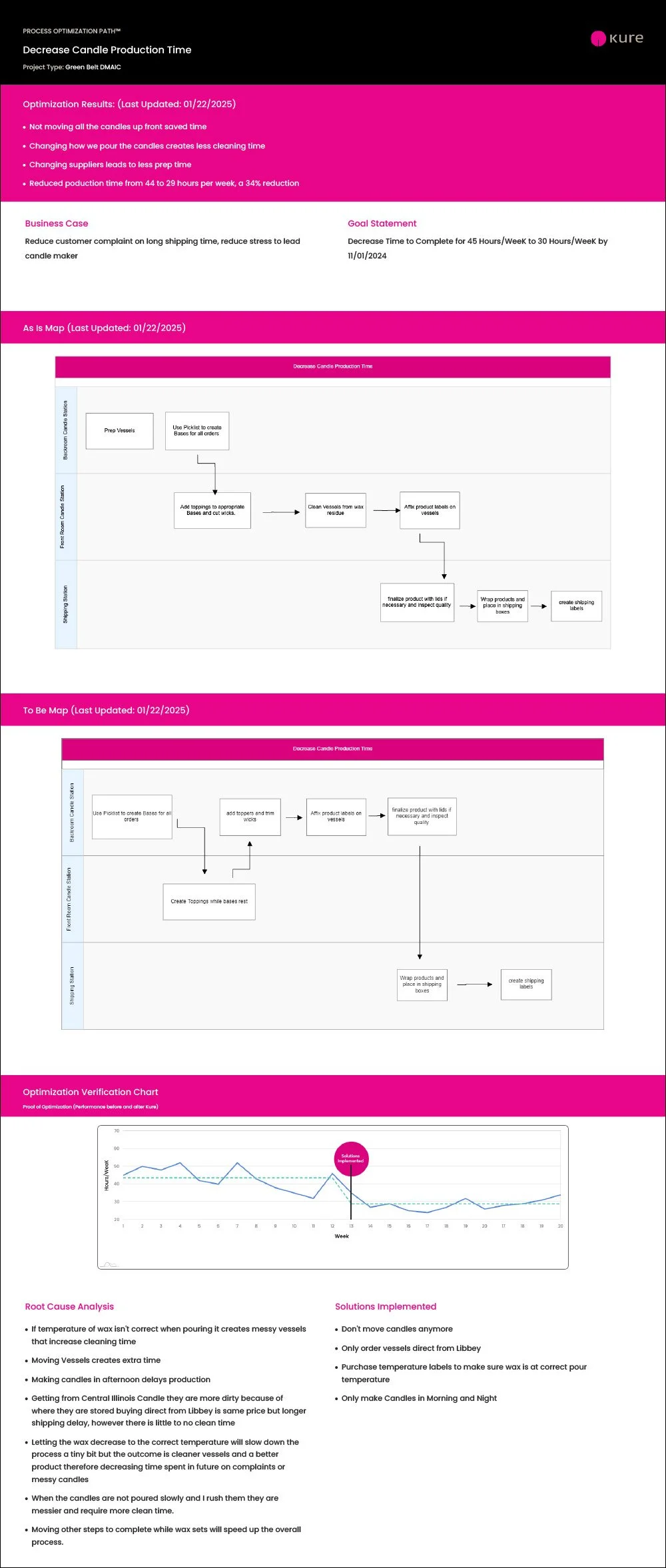

Problem: Luminara & Company faced production challenges in meeting customer demand. This excessive production time frustrated customers with late delivery and low inventory in the store, ultimately impacting the company’s reputation and revenue.

Determined to fix these issues, the organization partnered with GLSS’s Lean Six Sigma Green Belt Training & Certification. Their expertise in Lean Six Sigma provided the structured approach needed to reduce production time from 44 to 29 hours per week, a 34% improvement.

The Problem

Luminara & Company faced several production challenges that put pressure on the team and affected their ability to meet customer expectations. Orders were often delayed, store shelves sat empty, and employees were feeling overwhelmed. Hiring extra staff wasn’t financially feasible, and the production lead was stretched too thin. Customer complaints about long wait times for their favorite candles were mounting, and the business's reputation was at risk.

To tackle these challenges, a dedicated team of professionals, led by project leader Antonia Dietrich, was assembled. The team leveraged Kure's AI-driven workflow, which follows the DMAIC (Define, Measure, Analyze, Improve, Control) methodology to guide them through the entire process. Kure provided step-by-step support, offering expert guidance, practical suggestions, and AI-powered data analysis to help the team focus on solving the real problems.

The Root Causes

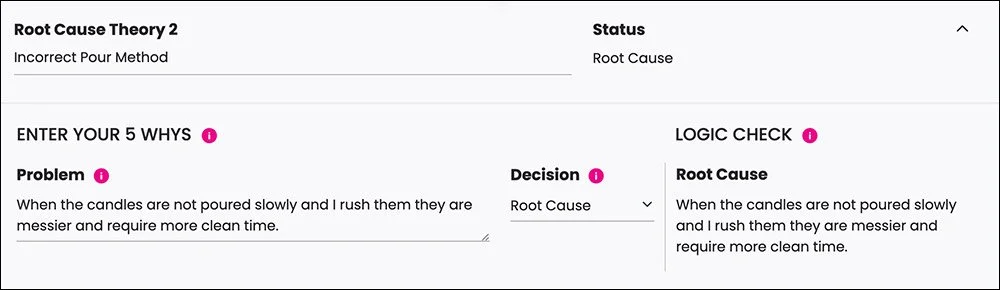

With Kure's insights, the team conducted a deep dive into their production process and uncovered several key areas contributing to delays:

Wax Temperature Inconsistencies: Wax poured at the wrong temperature led to messy candles and extra cleaning time.

Excessive Movement: Constantly moving candle vessels added unnecessary steps and increased production time.

Poor Production Timing: Afternoon production led to longer setting times and delayed progress.

Dirty Candle Vessels: Locally sourced vessels required extensive cleaning, adding extra steps to the process.

Rushed Pouring: Pouring wax too quickly created spills and required additional cleanup.

Idle Time: Valuable time was wasted waiting for candles to set instead of using it productively.

The Solutions

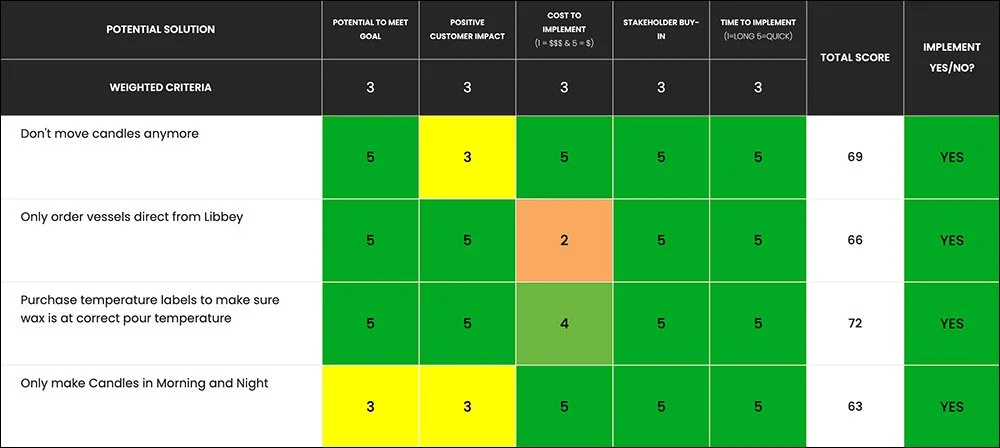

Guided by Kure’s AI-driven workflow, the team implemented simple but effective solutions that streamlined their operations:

Minimizing Movement: Once poured, candles were left in place to set, cutting down unnecessary handling.

Switching Suppliers: Ordering vessels from a premium supplier eliminated the need for pre-cleaning, saving time.

Using Temperature Labels: This ensured wax was poured at the optimal temperature every time, improving quality.

Adjusting Work Hours: Production was shifted to morning and evening hours for better efficiency.

Refining Pouring Techniques: Slower, more controlled pouring reduced spills and cleanup time.

Maximizing Idle Time: Instead of waiting, the team focused on other essential tasks during wax-setting periods.

The Results

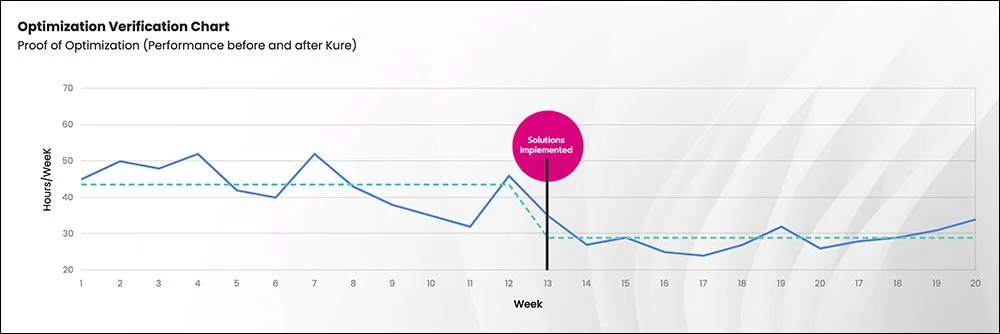

Thanks to these strategic improvements, the results were clear and immediate:

Faster Production: Streamlined processes and optimized idle time cut production time from 44 to 29 hours per week, a 34% improvement.

Higher Quality Products: Maintaining the right wax temperature resulted in cleaner, better-looking candles with less waste.

Happier Customers: Faster turnaround times meant fewer delays and more satisfied customers.

The lead candle maker, Antonia, experienced less stress, and the entire team felt more in control and confident in their ability to meet demand. Store shelves stayed stocked, and customers were thrilled to receive their candles on time.

Conclusion

Luminara & Company’s experience shows that even small process improvements can make a huge difference. By using Kure's AI-driven workflow, the team was able to identify inefficiencies, apply targeted solutions, and achieve incredible results quickly. Kure’s innovative approach provided valuable guidance, helping the team stay focused, make data-driven decisions, and complete the project up to three times faster than traditional methods.

With an optimized production process and a renewed focus on continuous improvement, Luminara & Company is set up for long-term success and future growth. The company now has the tools and strategies to keep operations running smoothly and efficiently, ensuring their candles continue to bring warmth to homes everywhere.