Manufacturer Reduces Prototype Production Time By 77% With Kure

PROJECT SUMMARY

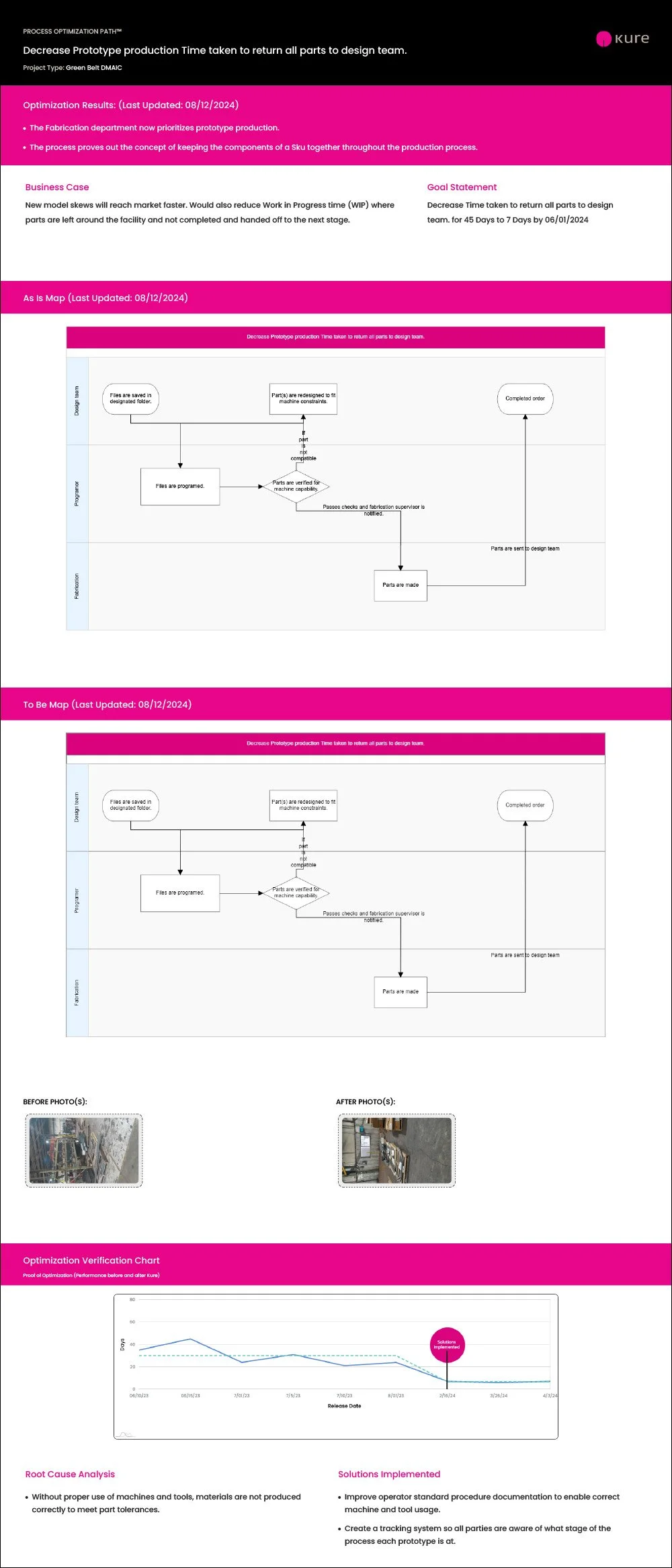

Business Case

New model SKUs will reach market faster. Would also reduce Work-in-Progress time where parts are left around the facility and not completed and handed off to the next stage.

Root Cause Analysis

Without proper use of machines and tools, materials are not produced correctly to meet part tolerances.

Solutions Implemented

Improve operator standard procedure documentation to enable correct machine and tool usage.

Create a tracking system so all parties are aware of what stage of the process each prototype is at.

Project Results

The Fabrication department now prioritizes prototype production.

The process proves out the concept of keeping the components of a SKU together throughout the production process.

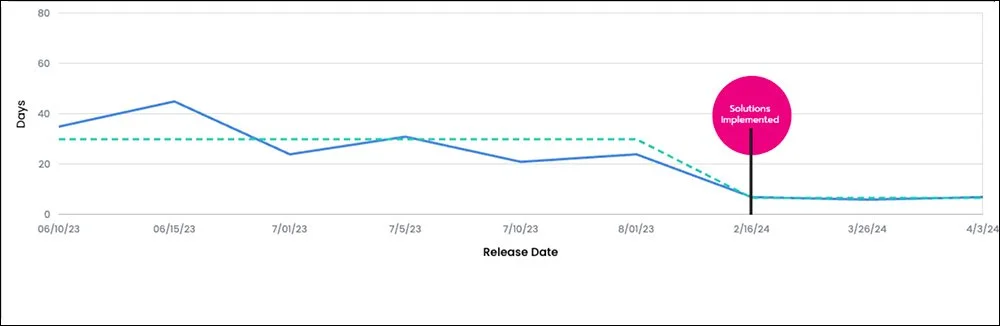

Lead times were reduced from 30 days to 7 days—a 77% improvement!

Summary

The problem: Lead time for prototype production was taking 30 days, leading to delays, increased costs, and unsatisfied customers.

With Kure, this manufacturer developed standard operating procedures and implemented a robust tracking system, reducing lead time to 7 days—a 77% improvement—and allowing them to deliver products to their customers faster than ever before!

The Problem

The prototype production process was struggling with delays, which were leading to longer lead times and increased costs. This manufacturer realized that in order to stay competitive, they needed to identify and eliminate the root causes of these delays. However, the complexity of the problem made it difficult to pinpoint exactly where things were going wrong. They needed a solution that would help them quickly and accurately analyze their processes, identify the issues, and implement effective changes.

The Approach

To tackle this challenge, they assembled a team of skilled professionals led by an experienced project manager. They decided to use Kure, an AI-powered process improvement software that leverages the DMAIC methodology (Define, Measure, Analyze, Improve, Control). Kure guided them through each step of the project, offering examples, suggestions, and even AI-driven data analysis to help them focus on solving the problem rather than getting bogged down in the details. This approach allowed them to streamline their work and complete the project in a fraction of the time it would have taken otherwise.

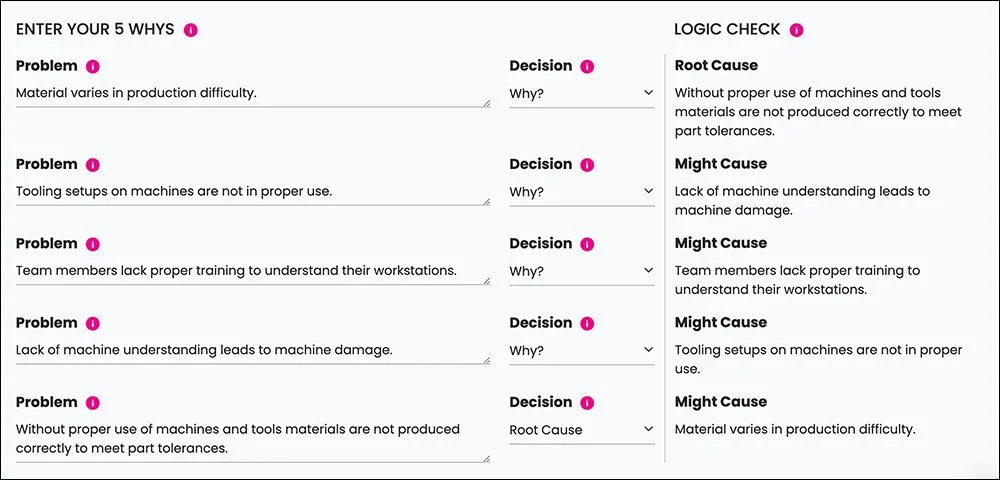

The Root Causes

Using Kure's structured workflow, they were able to dive deep into our processes and uncover the root causes of their production delays. They found that inconsistent scheduling was creating bottlenecks, while a lack of standardized procedures led to variability in their output. Additionally, communication gaps between departments were causing misalignment, further exacerbating the delays. By identifying these issues, they could develop targeted solutions to address them.

The Solutions

With the root causes identified, they set about implementing changes that would streamline their production process. They standardized their procedures, ensuring that everyone followed the same guidelines, which significantly reduced variability. They also overhauled their scheduling system, making it more robust and capable of coordinating efforts across departments. Improved communication channels were established to ensure that everyone was on the same page and working towards the same goals. Kure’s guidance throughout this process was invaluable, helping them stay focused and on track.

Before and After

The Results

The impact of these changes was profound. They managed to reduce lead times by 77%, from 30 days to 7 days, which allowed them to meet customer demands more effectively and improve their overall efficiency. Operational costs dropped significantly as a result of the streamlined processes, and the team’s morale improved as they saw the tangible benefits of their hard work. The Kure workflow not only helped them resolve their immediate issues, but also positioned them for long-term success by embedding a culture of continuous improvement.

Conclusion

This project marked a turning point for their organization. By using Kure’s innovative process improvement workflow, they were able to achieve results much quicker than they could have imagined. The AI-driven analysis and structured guidance provided by Kure allowed them to focus on solving the real problems rather than getting lost in the complexity.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.