Postal Service Reduced Damaged Parcel Processing Time By 50% With Kure

PROJECT SUMMARY

Problem: At this Postal Service, things were going smoothly until they opened a new plant in 2023. Suddenly, they experienced a sharp increase in damaged parcels, taking an average of 6 minutes per parcel to process. This slowed everything down.

Result: With help from Kure, an AI-powered process improvement platform, the depot reduced the processing time to 3 minutes per parcel—a 50% improvement.

The Problem

At a busy postal depot in North York, Canada, teams were proud of how smoothly operations ran—until a major expansion changed everything. After opening a new parcel processing plant in 2023, the depot was suddenly overwhelmed by a surge in damaged packages. The unexpected volume slowed things down and made it harder to meet delivery goals.

In the parcel delivery business, speed matters. Every delay has a ripple effect, and damaged parcels need special attention—fast. After the expansion, this depot saw a 70% increase in damaged packages, and each one was taking an average of 6 minutes to process—twice as long as regular shipments.

Before

As more and more time was spent on handling damaged items, the rest of the operation started to fall behind. Delivery times slipped, key performance indicators dropped, and employees felt overwhelmed. It wasn’t just a workflow issue—it was impacting customer satisfaction and employee well-being.

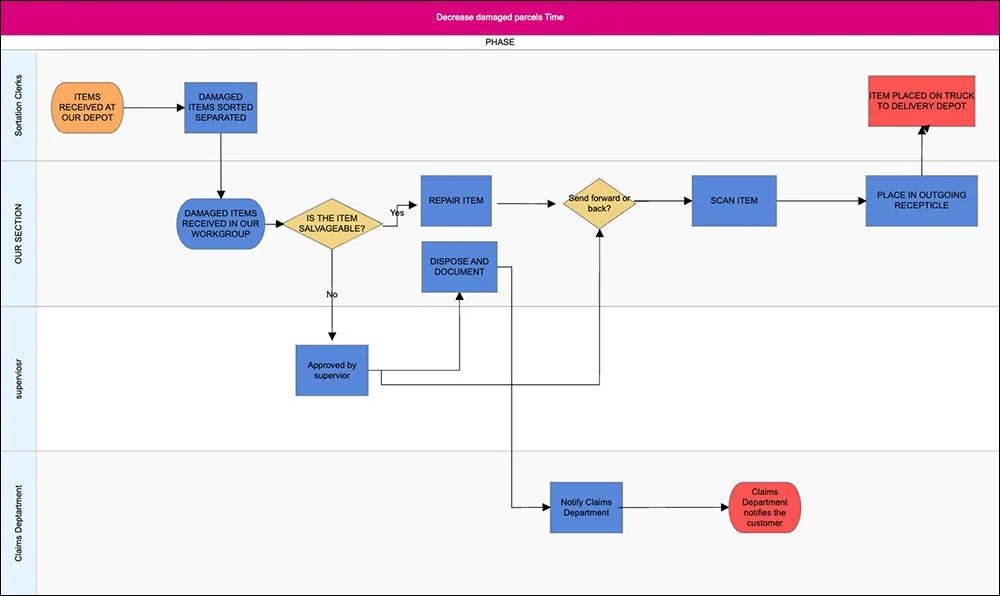

To get things back on track, a skilled team led by a project leader undergoing Lean Six Sigma Green Belt Training & Certification was assembled. They used Kure’s DMAIC-based improvement workflow to map the current process, pinpoint the causes of delays, and build practical solutions faster so they could focus on the work that mattered most.

Determined to fix the issue without adding more pressure to an already stretched team, they turned to Kure, an AI-powered process improvement tool that walks teams step-by-step through improvement projects. With built-in examples, smart suggestions, and data-driven guidance, Kure helps teams solve problems up to three times faster—and that’s exactly what they needed.

The Root Causes

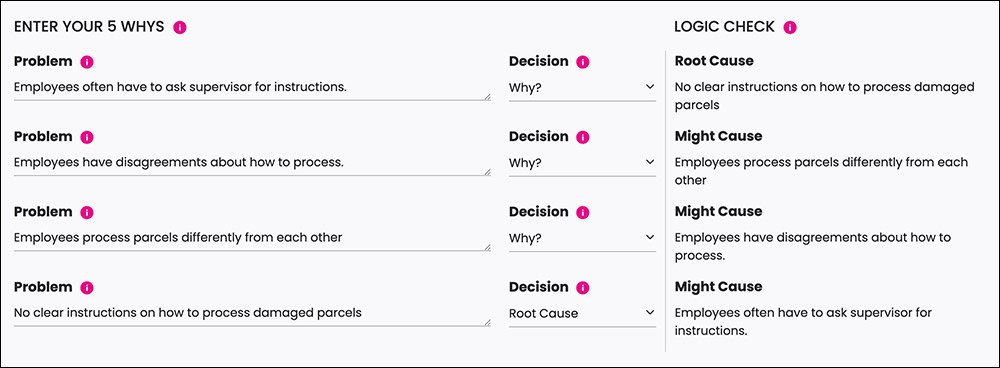

Kure guided the team through their analysis, helping them uncover four major reasons why damaged parcels took so long to process:

No standard process meant every employee handled parcels differently, leading to confusion, delays, and repeated approvals.

Too many team members working in pairs created crowding and delays at shared tools like shipping computers.

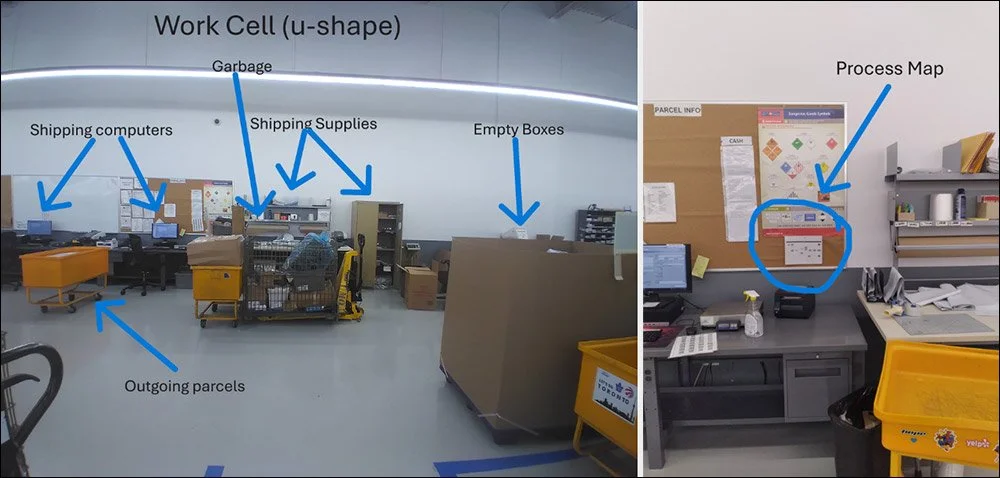

Inefficient layout required staff to walk long distances just to get basic tasks done.

Multiple groups taking turns on the same task added setup time, miscommunication, and waste.

The team also used the lens of Ethical Efficiency™ to ask an important question: Are we making this process better for both the business and the people doing the work? The answer helped them stay focused on solutions that were not only efficient but also fair, sustainable, and supportive of everyone involved.

The Solutions

With help from Kure’s smart suggestions and easy-to-use templates, the team quickly put improvements into action:

They designed a clear, step-by-step process for handling damaged parcels and posted a visual guide where everyone could see it.

They switched to a dedicated two-person team focused solely on damaged parcel processing, reducing overlap and confusion.

A new U-shaped workstation was created, placing all tools and supplies within reach—cutting out unnecessary movement and saving time.

These changes weren’t just faster—they were also better for employee wellbeing. Fewer interruptions, clearer roles, and a more thoughtful setup helped reduce stress and frustration.

The Results

The changes paid off right away. The average processing time for damaged parcels dropped from 6 minutes to just 3 minutes—a 50% improvement.

Even more importantly, staff felt more confident, less rushed, and better able to manage their work. With a smoother process and fewer delays, the team was able to meet delivery goals again—without sacrificing quality or burning out employees.

Conclusion

After

By using Kure’s AI-driven process improvement workflow, the postal depot didn’t just fix a problem—they made their operations smarter, faster, and more respectful of the people doing the work. Kure helped the team stay focused, make informed decisions, and move quickly from problem to solution.

This project showed how Ethical Efficiency™ can guide improvements that work for both the organization and its people. Now, with a proven solution in place and a team equipped to take on more challenges, the depot is better prepared than ever to grow—and do it the right way.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.