Global Fortune 500 Company Reduces Line Changeover Time By 32% With Kure

PROJECT SUMMARY

Business Case

Increased production, reduced overtime, increased customer service levels

Root Cause Analysis

Infrastructure not maintained

Need has not been previously identified to change logic

Solutions Implemented

Find additional line to utilize

Project Results

Reduced daily changeover by 33 minutes

The Challenge

In the volatile Oil & Gas industry, agility drives success. At this Texas operation, one significant challenge was the lengthy and inconsistent changeover times for a critical operation. The excessive changeover times not only slowed down production but also led to increased costs, overtime, and decreased productivity. The goal was clear: reduce the line changeover time by at least 20% to enhance operational efficiency and meet production targets.

The Approach

A team consisting of skilled professionals from various departments, including production, maintenance, quality control, and logistics, was assembled to meet the challenge. The team was led by Terry*, an experienced project manager who was participating in online Lean Six Sigma Green Belt Training & Certification from GLSS. Terry knew that applying the training immediately to an important project was the most effective way to learn while also achieving valuable results.

Terry also chose Kure, the AI-powered process improvement software, which organizes and automates all the process improvement work in one place. Terry knew that Kure would greatly speed up the project work and allow the team to focus more on problem-solving and less on status reports and cumbersome software.

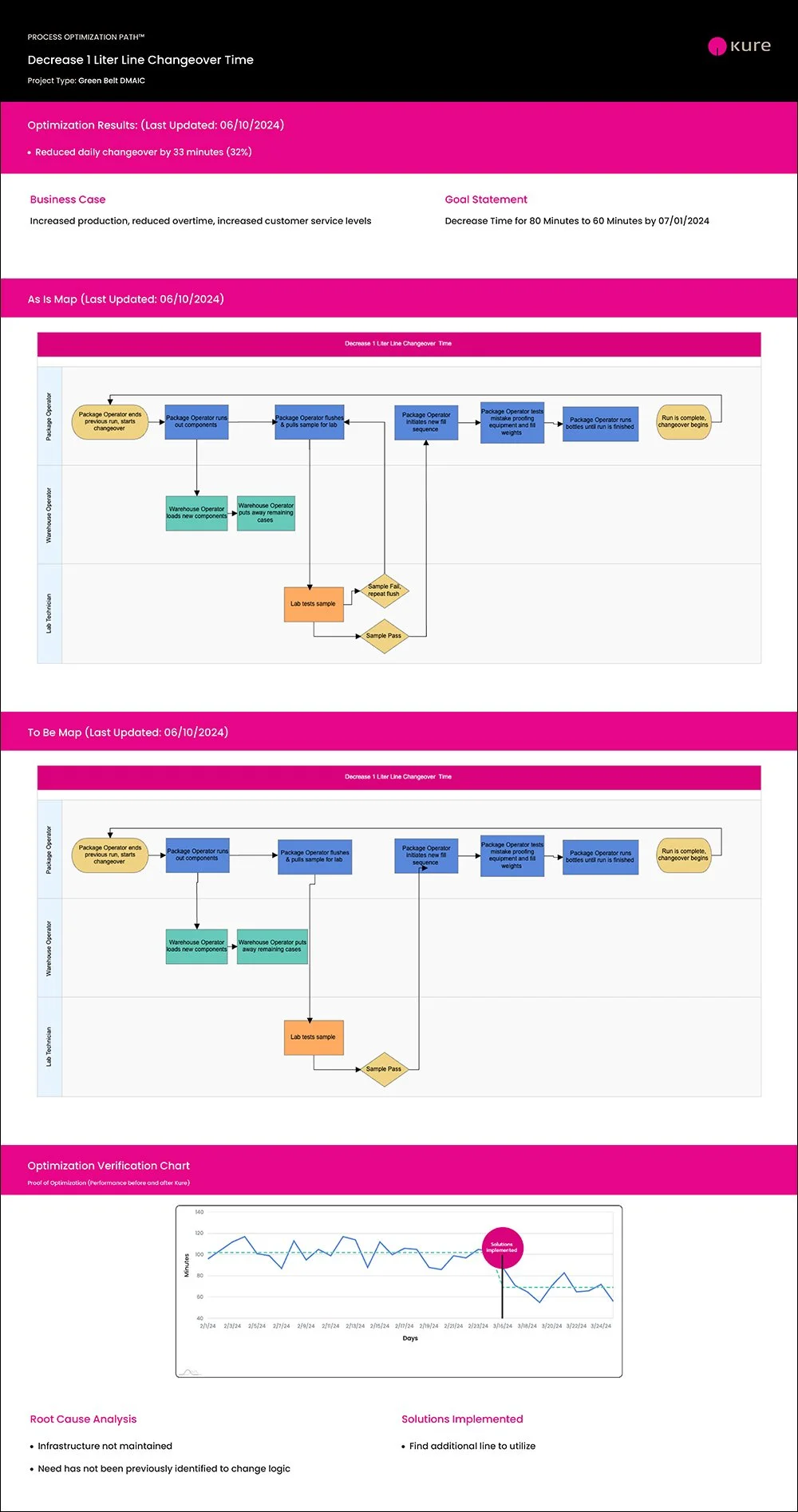

Define

Terry initiated an assessment of the current, As-Is, changeover process using Kure Process Improvement Software. This involved defining the Project Scope and objectives clearly and setting a goal of reducing changeover times by at least 20%.

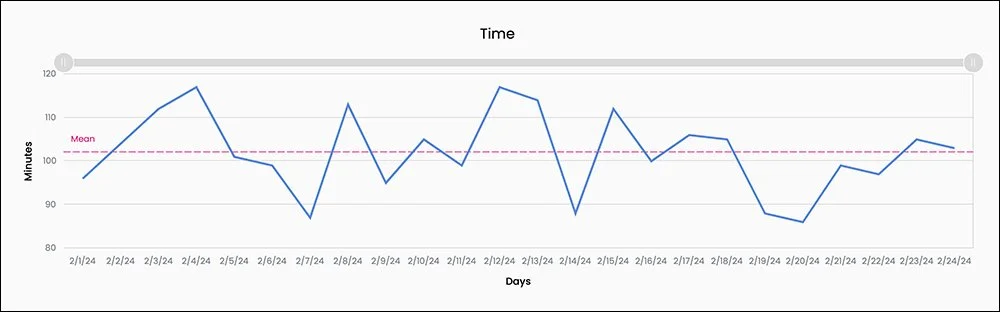

Measure

Using Kure's guidance, the team employed Process Mapping to understand all the steps in the process and Data Collection to analyze the time and effort required throughout the changeover. This assessment revealed a couple of surprises:

A critical flushing operation took over 40 minutes, much longer than expected.

The line control logic would not allow the next process sequence to initiate, thus slowing the changeover process.

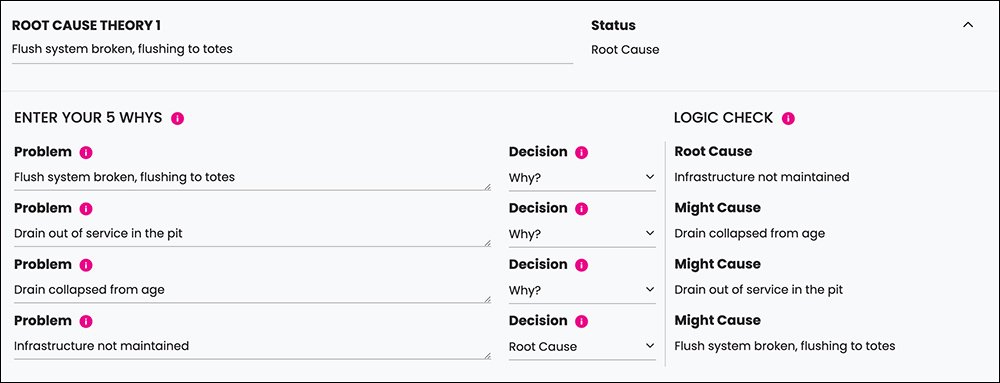

Analyze

The team conducted a root cause analysis using Kure's Fishbone Diagram, 5 Whys, and Hypothesis confirmation. This analysis uncovered more surprises:

The root cause of the excessive flushing time was a drainage system supporting the line that had not been maintained over the years and was no longer working. Therefore, a cumbersome manual flushing operation was being used. This manual process had been used for so long that it was assumed it was how it was always done.

The need for a simple logic change in the process control system had never been identified as a need. It would be easy to correct.

Improve

The team focused on implementing solutions using Kure's structured Solution Selection Matrix and Implementation planning tools. They standardized the changeover process, trained crews, and edited the process control logic. Additionally, a new drainage line was installed, resulting in a quicker flush with no manual work.

Control

To sustain the improvements, the team established a Monitoring & Response Plan, standardized procedures, and improved communication channels. Enhanced equipment reliability and better-trained staff minimized errors and delays. The team continued to monitor the process using Kure's control tools to ensure the improvements were maintained over time.

Conclusion

The implementation of these solutions led to a significant reduction in line changeover times. The team reduced the changeover time from 102 to 69 minutes, a 32% improvement, exceeding the initial goal. This project highlights the importance of a structured approach to problem-solving using Kure Process Improvement Software, which often leads to surprisingly simple but impactful solutions. For the company, this success sets a benchmark for future projects and reinforces its commitment to continuous improvement and operational excellence.

The journey doesn't end here. The company will continue to refine its processes, invest in its people, and leverage new technologies to maintain its competitive edge. The lessons learned and the success achieved in this project will undoubtedly guide them in future efforts.

*We value our clients' confidentiality. While we've changed their names, the results are real.