Lab Equipment Manufacturer Decreased Return Material Authorization Turnaround Time By 55% With Kure

PROJECT SUMMARY

The problem: the average Return Material Authorization turnaround time had averaged around 33 days, well over the target. These long delays were driving customer frustration, increasing complaints, and costing the company significant service revenue.

Using Kure, the team rolled out a series of focused improvements and reduced the RMA turnaround time from 33 to 15 days—a 55% improvement.

The Problem

In the lab equipment industry, timely service is critical to customer satisfaction and long-term success. When instruments need repairs or maintenance, customers expect fast turnaround without sacrificing quality. One organization faced a growing problem: their Return Material Authorization (RMA) turnaround times were far too long, leading to complaints and lost revenue. To solve the issue efficiently, the company turned to Kure, a digital improvement platform that provides step-by-step guidance and automatically documents the entire process, helping teams get better results faster.

The company had clear internal targets—5 days for warranty repairs and 7 days for other service work—but reality told a different story. Since 2022, the average turnaround time had ballooned to 33 days. This gap was eroding customer trust, creating backlogs, and reducing monthly service revenue. The team set an ambitious goal: cut RMA turnaround time by 50%, identify root causes, and implement sustainable improvements.

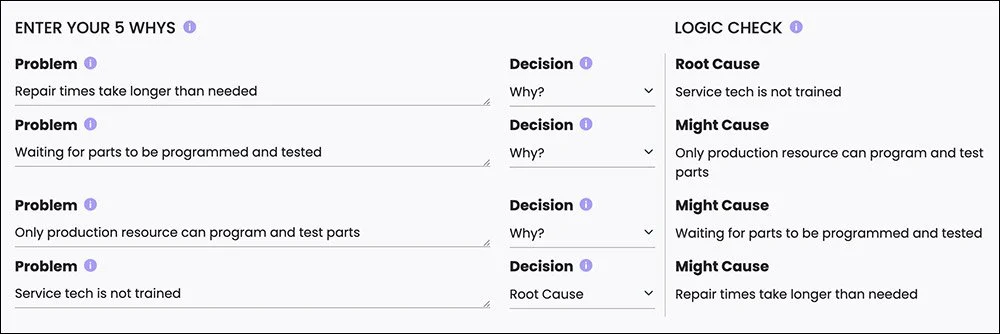

The Root Causes

Using Kure’s structured approach, the team quickly pinpointed several contributing issues:

The RMA initiation process was inefficient, requiring copy-and-paste work into Word documents instead of using system-generated reports.

A hiring freeze limited the availability of skilled labor.

Technicians lacked training to program and test critical components.

The factory didn’t have enough tools, carts, or test fixtures, causing delays due to equipment sharing and waiting times.

Kure enabled the team to collect and analyze these findings collaboratively, accelerating the diagnostic phase and ensuring all stakeholders had visibility.

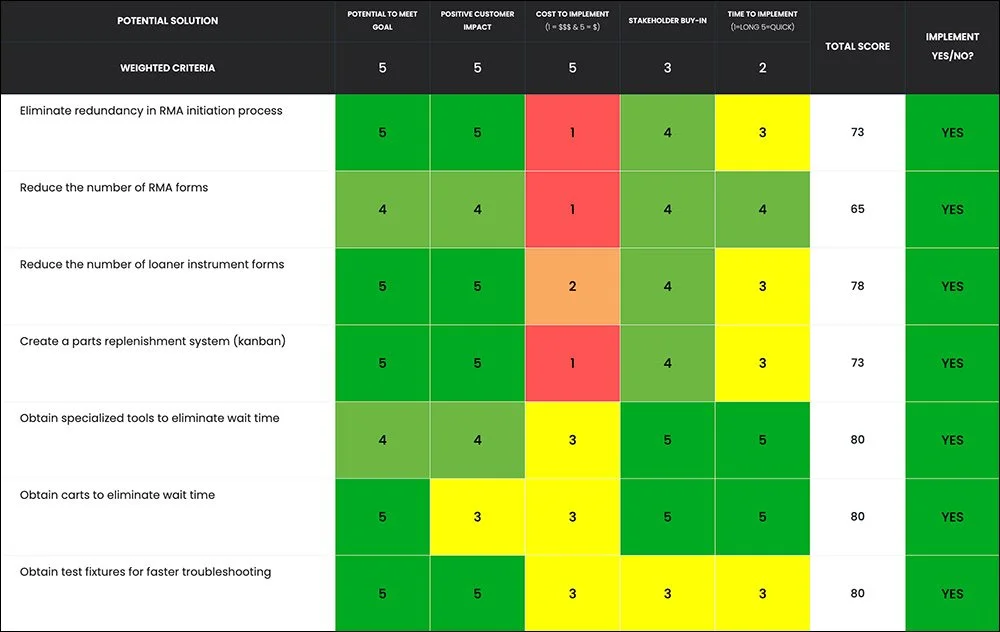

The Solutions

With Kure guiding the project, the team rolled out several high-impact changes:

Eliminated redundant forms in the RMA process and used Crystal Reports in SAP to streamline documentation—saving time and reducing errors.

Reduced the number of loaner instrument forms, simplifying the service workflow.

Introduced a Kanban system for replenishing factory parts, removing bottlenecks caused by stockouts.

Acquired specialized tools, test fixtures, and additional carts to reduce technician downtime.

Cross-trained field service technicians in Quality Control inspections, helping the team maintain a 2-day QC turnaround while keeping the RMA pipeline moving.

Rotated field techs through the factory, relieving travel-related stress and improving team integration.

Throughout the effort, Kure’s platform automatically documented progress, actions, and results—eliminating the need for extra reporting and helping the team stay focused.

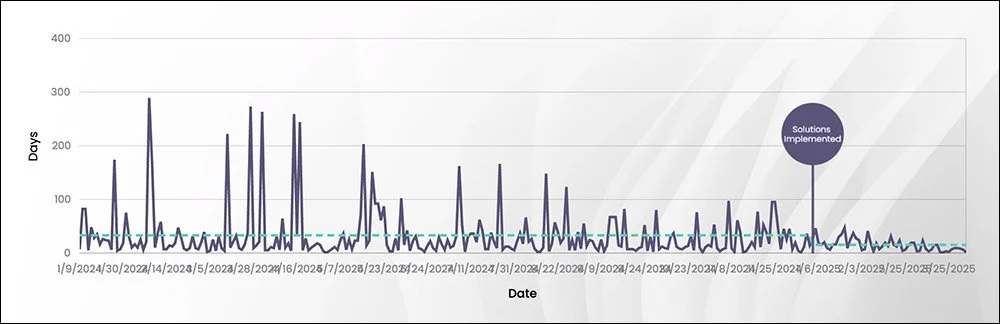

The Results

Before & After

The improvements were swift and significant. The average RMA turnaround time dropped from 33 to 15 days, exceeding the 50% reduction goal. Automating RMA initiation saved 10 minutes per case and eliminated numerous forms, contributing to an annual cost savings of $1,075.78.

The Kanban system removed delays from missing parts, and better tool access improved repair efficiency. Faster turnaround allowed for quicker billing, resulting in a projected annual revenue increase of $124,000. Additionally, field tech rotations led to better collaboration and a projected $42,476 in annual travel savings.

Conclusion

By choosing Kure to manage the project, the organization was able to move from problem to solution faster than ever before. Kure’s intuitive, guided structure kept the team on track, while automatic documentation ensured transparency and sustainability. The outcome wasn’t just a shorter RMA cycle—it was a stronger, smarter service operation. Thanks to Kure, the company is now delivering faster service, improving customer satisfaction, and growing its factory service revenue with confidence.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.