Manufacturer Increased Epoxy Production Output By 45% With Kure

PROJECT SUMMARY

The problem: The manufacturer was consistently missing projected ship dates for epoxy-filled parts. Orders took longer than expected to complete, which led to higher labor costs and growing frustration on the shop floor.

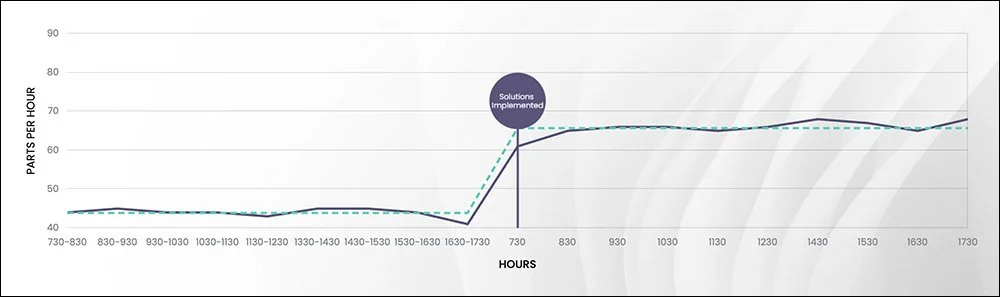

Using Kure, the team was able to produce 20 more parts per hour on average, from 44 parts to 64 parts—a 45% improvement.

The Problem

In the world of manufacturing, speed and accuracy are key. Every delay in production doesn’t just affect the bottom line—it impacts customer satisfaction and employee morale. That’s exactly what one manufacturer was experiencing with their epoxy-filled parts. Orders were late, labor costs were rising, and frustration was building on the shop floor.

To get back on track, the company turned to Kure, a powerful improvement management platform designed to help teams solve problems faster with step-by-step guidance and built-in documentation. Kure also aligned with the company’s commitment to Ethical Efficiency™—a people-first approach that combines doing what’s right with doing what works. It was the perfect fit for a team ready to make meaningful, measurable change.

The company was struggling to meet its projected ship dates. The epoxy process was taking too long, and orders were constantly running behind schedule. Not only did this put customer relationships at risk, but it also meant higher labor costs and rising stress for team members.

In the competitive manufacturing space, process delays can have a ripple effect—missed deadlines, lost revenue, and frustrated teams. Leadership knew they needed to move quickly and make a fix that would last.

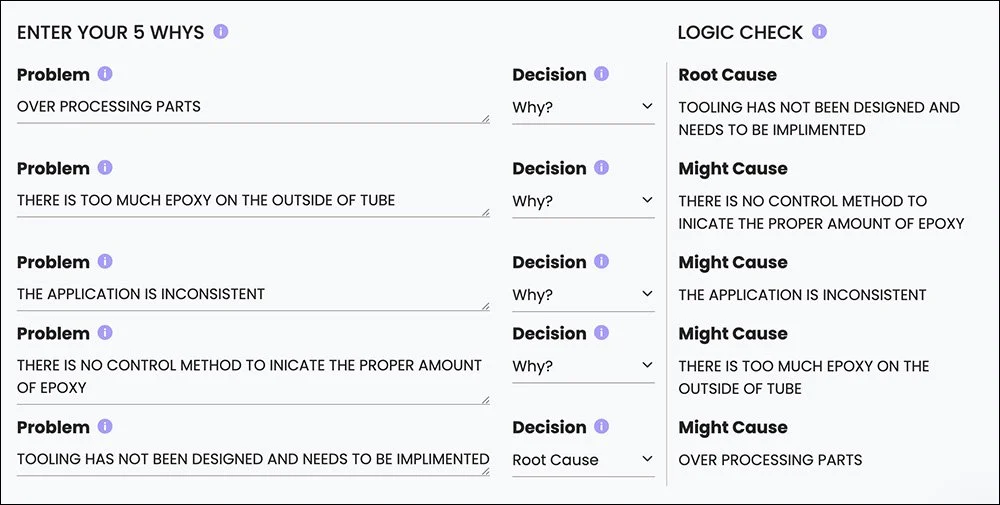

The Root Causes

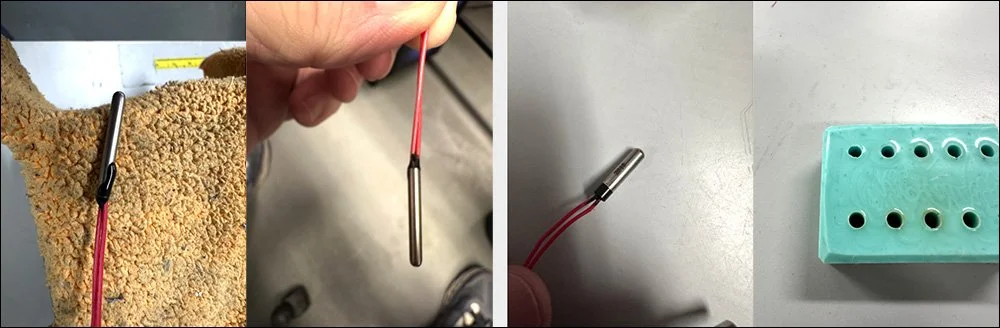

Guided by Kure’s structured approach, the team explored what was really causing the hold-ups. They discovered that the tooling used for epoxy filling wasn’t up to speed. Workers were trying to manually guide the epoxy into parts, but the process was clunky and inconsistent.

The old molds didn’t hold the tubes firmly or guide the epoxy properly, which led to overfilling, rework, and wasted time. Even with everyone working hard, the tools were holding the team back.

The Solutions

With Kure leading the way, the team was able to clearly define the problem, map out causes, and quickly collaborate on solutions. The answer? A redesigned mold that would hold each tube securely and ensure the epoxy filled correctly—no overflow, no wasted effort.

Kure made every step simple. It helped the team document the issue, track progress in real-time, and stay aligned without needing a pile of spreadsheets or slide decks. The result was a smart, efficient solution delivered faster than anyone expected.

The Results

Before & After

The improvement was immediate and dramatic. With the new mold in place, the team boosted their output from 44 to 64 parts per hour—a 45% increase. That meant fewer delays, lower labor costs, and more satisfied customers.

The process also became much smoother for workers. Instead of fighting the equipment, they had tools that supported their success. Morale improved, and the shop floor felt more focused and energized.

Best of all, the entire project moved faster because of Kure. With every step built into the platform—and automatic documentation along the way—there was no guesswork, no confusion, and no wasted time.

Conclusion

This project was more than a quick fix—it was a clear example of how the right tools can unlock long-term success. By using Kure, the team solved a complex production issue quickly and confidently. The platform’s smart design gave them structure, speed, and visibility, all while reinforcing their commitment to Ethical Efficiency™—an approach that balances results with respect for people and process.

Now, with a smoother epoxy process and a stronger improvement mindset, the company is better equipped to meet demand, deliver on promises, and continue growing. And thanks to Kure, they have a repeatable path to tackle the next challenge—efficiently, ethically, and effectively.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.