Manufacturer Decreased Preventive Maintenance Start Time By 50% With Kure

PROJECT SUMMARY

The problem: In the fast-moving world of manufacturing, every second matters. Preventive maintenance (PM) plays a crucial role in keeping machines running smoothly, but inefficiencies in the process can lead to costly downtime. For one manufacturer, a simple yet frustrating issue was slowing down maintenance teams and making their jobs harder than necessary.

The company needed a solution that would eliminate wasted time and improve efficiency—so they turned to Kure, an AI-powered process improvement software that provides teams with guided workflows, expert recommendations, and data-driven insights to streamline problem-solving and complete projects up to three times faster.

The Problem

Keeping production lines running efficiently depends on well-organized and timely maintenance. However, maintenance teams at this company were running into a major obstacle: gathering supplies for preventive maintenance took too long. Instead of focusing on keeping equipment in top shape, employees spent valuable time tracking down the tools and materials they needed—scattered across different areas of the facility.

This wasn’t just a minor inconvenience; it was a major disruption that slowed operations, increased labor costs, and put additional strain on employees. To stay competitive, the company needed a better system—one that would reduce wasted time, improve efficiency, and make life easier for the maintenance team.

To solve this challenge, the company brought together a team of skilled professionals, led by a project leader using Kure’s AI-driven process improvement workflow. Kure guided the team through the DMAIC (Define, Measure, Analyze, Improve, and Control) methodology, helping them pinpoint inefficiencies, find solutions, and implement changes quickly.

Before

The Root Causes

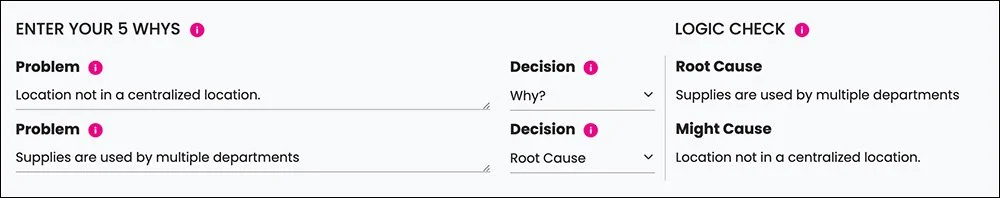

By using Kure’s AI-driven analysis, the team identified three major reasons why the PM supply collection process was inefficient:

Shared Supplies Across Departments: Maintenance staff had to track down tools and materials that were used by multiple teams, leading to frequent shortages.

No Centralized Storage: There wasn’t a single, organized location where all PM supplies were kept.

Scattered Storage Areas: Employees had to move between multiple locations just to gather everything they needed, wasting valuable time.

The Solutions

Guided by Kure’s intelligent workflow, the team took a straightforward yet highly effective approach to solving the problem: they created a centralized storage system for all preventive maintenance supplies.

With all the necessary tools and materials in one dedicated location, employees no longer had to waste time searching for what they needed. Kure provided step-by-step guidance on optimizing the storage layout, ensuring accessibility, and implementing standardized processes to keep everything organized.

This simple but powerful change streamlined the entire PM process, reducing unnecessary movement, improving organization, and helping maintenance teams get their jobs done faster and with less frustration.

The Results

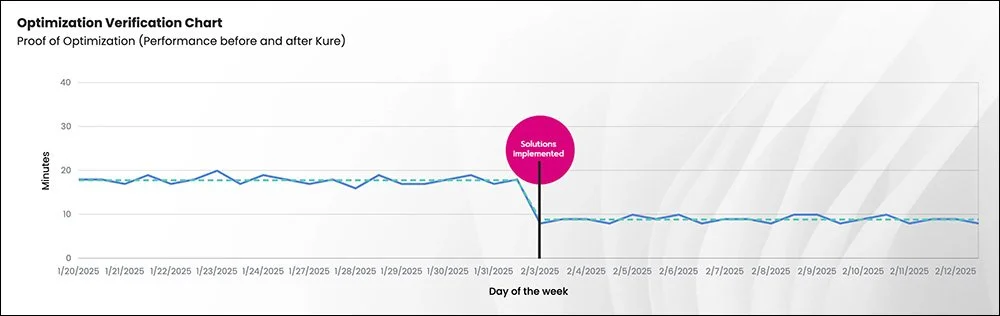

Thanks to Kure’s AI-driven guidance, the company saw immediate and measurable improvements:

50% reduction in time spent gathering supplies, from 17.8 to 8.9 minutes.

Faster, smoother, and more efficient preventive maintenance

Happier, less frustrated employees who could focus on their jobs

With a more organized workflow, maintenance teams could now dedicate their time to keeping equipment running at peak performance, rather than wasting energy tracking down supplies. Not only did this improve overall productivity, but it also created a more supportive and efficient work environment for employees.

Conclusion

This success story highlights how AI-powered process improvement can drive real, measurable change. With Kure’s step-by-step workflow, expert suggestions, and advanced data analysis, the company was able to quickly pinpoint inefficiencies, implement solutions, and see results up to three times faster than traditional methods.

By taking a structured yet flexible approach to problem-solving, Kure helped the team reduce wasted time, improve efficiency, and set the foundation for long-term operational success. This project is a perfect example of how smart process improvements can make a big impact—not just on the bottom line, but on employee satisfaction and overall productivity.

After

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.