Manufacturer Increased Production By 30% With Kure

PROJECT SUMMARY

The problem: A leading industrial equipment manufacturer faced a critical challenge: their high-volume roller conveyor production wasn't keeping pace with growing customer demand.

By embracing Kure’s innovative AI-driven process improvement technology, they transformed their operations and achieved a remarkable 30% improvement.

The Problem

In an era where manufacturing efficiency determines market leadership, a prominent industrial equipment manufacturer faced a pressing challenge. Their production of high-volume roller conveyors couldn't match the surging customer demand.

The manufacturing floor was caught in a web of inefficiencies that threatened the company's market position. Daily operations were hampered by extended setup times, inconsistent processes, and communication challenges. These weren't merely operational hiccups – they translated into delayed deliveries, stressed employees, and lost business opportunities.

Rising costs and evolving customer expectations made it clear that maintaining current practices wasn't sustainable. The leadership team recognized the urgent need for a data-driven approach to process improvement that would deliver both immediate results and long-term benefits.

To tackle these challenges, the company assembled a dedicated team led by a project leader pursuing Lean Six Sigma Green Belt Training & Certification. The team leveraged Kure, an innovative AI-powered process improvement platform that guides teams through the DMAIC methodology while providing real-time analysis, suggestions, and examples. This combination of human expertise and artificial intelligence set the stage for a dramatic transformation.

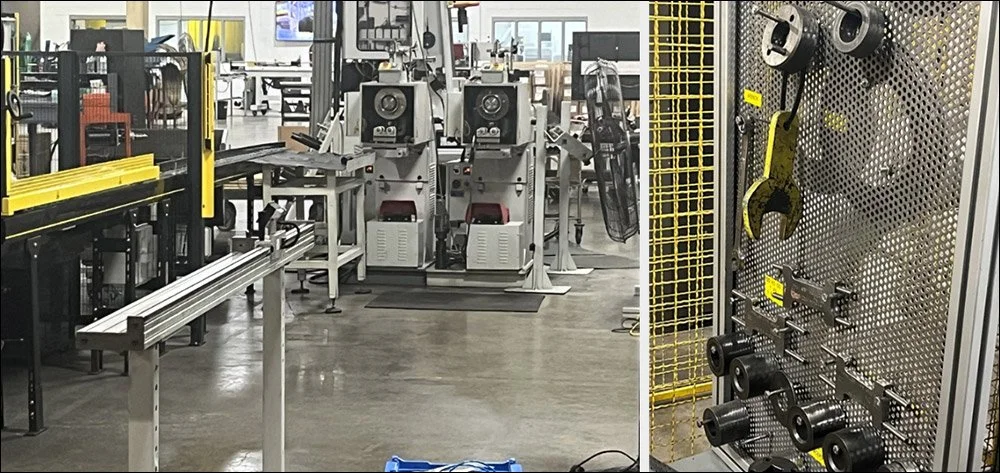

Before

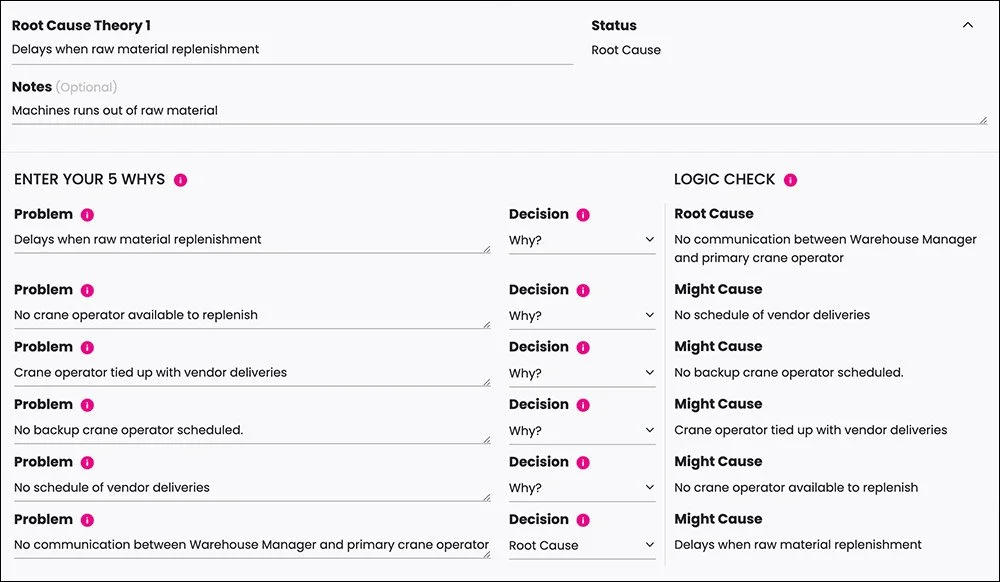

The Root Causes

Using Kure's advanced analytics capabilities, the team uncovered four critical issues:

Workflow bottlenecks stemmed from poor coordination between machine operators and supervisors

Communication barriers caused confusion during shift transitions and key operations

Material supply delays created unexpected production interruptions

Variations in equipment setup lead to inconsistent product quality

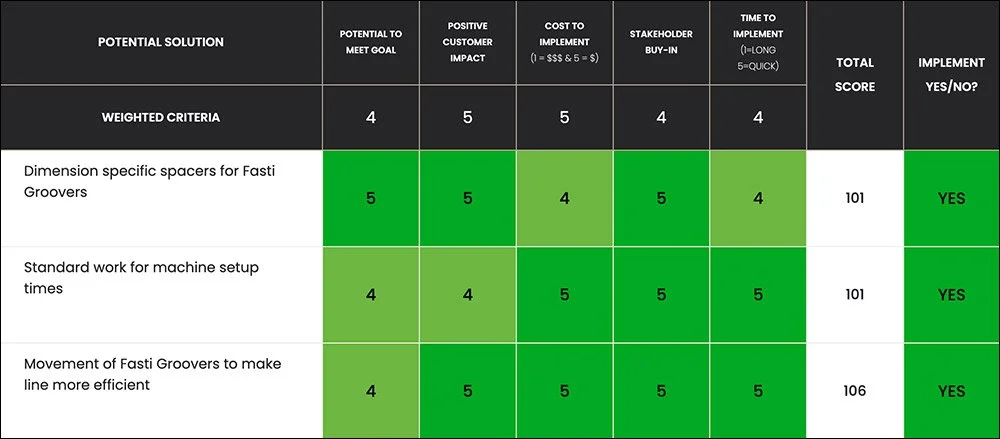

The Solutions

Guided by Kure's AI-powered workflow and recommendations, the team implemented targeted solutions:

Engineered precision-based setup tools that eliminated guesswork

Developed clear visual instructions that bridged language gaps

Optimized the production floor layout based on data-driven insights

Created a robust communication system featuring daily team huddles

Established standardized procedures that simplified operator training

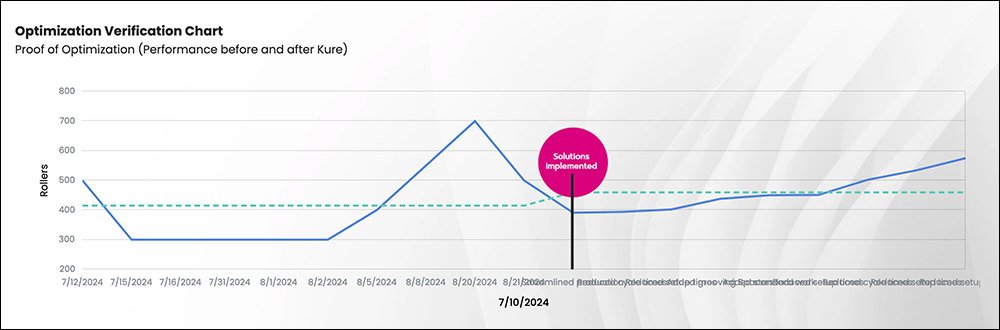

The Results

The impact was transformative, with production soaring from 415 to 537 units per shift – a 30% increase. The improvements reached across multiple areas:

Dramatically reduced production cycle times

Setup times slashed by 50%

Enhanced team communication leading to fewer errors

Improved employee satisfaction through streamlined processes

Increased production capacity without additional resources

Better quality metrics resulting in higher customer satisfaction

After

Conclusion

This success story demonstrates the power of combining human expertise with AI-driven process improvement technology. Kure's intelligent workflow system accelerated the team's progress, helping them achieve in weeks what traditionally took months. The platform's ability to provide real-time guidance, analysis, and suggestions enabled the team to focus on implementing solutions rather than getting bogged down in methodology.

The transformation went beyond numbers, creating a new culture of continuous improvement supported by data-driven decision-making. With Kure's AI capabilities at their disposal, the organization is well-equipped to replicate this success across other areas of operation, securing their competitive advantage in the fast-paced manufacturing sector. This project marks the beginning of their journey toward sustained operational excellence, powered by the perfect blend of human ingenuity and artificial intelligence.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.