Manufacturer Reduced Dirty Parts Returns By 100% With Kure

PROJECT SUMMARY

The problem: A Virginia-based manufacturer was facing a challenge that threatened their reputation and bottom line: customers were regularly receiving dirty parts after cleaning services. With an average of eight parts per month being returned due to cleanliness issues, customer confidence was eroding fast.

What changed their fortune? The company embraced cutting-edge process improvement technology and completely transformed their operation. By implementing targeted solutions based on data-driven insights, they achieved what once seemed impossible—a perfect 100% reduction in dirty parts returns!

The Problem

In today's manufacturing world, quality isn't just important—it's everything! When customers receive parts that don't meet cleanliness standards, the negative impacts spread like wildfire. For this manufacturer, each dirty part that reached a customer triggered a cascade of problems: unhappy clients voiced complaints, valuable team members had to stop their regular work to handle rework, and worst of all, hard-earned business relationships began showing cracks.

With every dirty part that left their facility, the company's reputation for quality and reliability took another hit. Customer disappointment was mounting, and leadership knew they needed to act decisively before permanent damage occurred.

A team of skilled professionals, led by a project leader pursuing Lean Six Sigma Green Belt Training & Certification, came together to address this pressing challenge. The team leveraged Kure, an innovative AI-powered process improvement platform that guides teams through the DMAIC methodology with interactive examples, step-by-step guidance, and powerful data analysis capabilities. This technology-driven approach allowed them to focus less on process paperwork and more on solving the actual problem.

The Root Causes

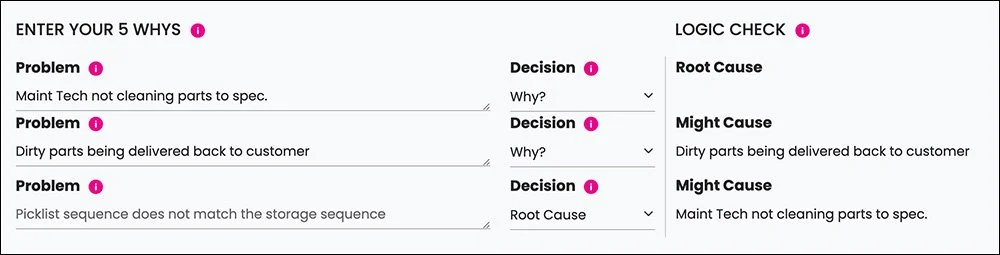

Using Kure's AI-powered analysis tools, the team dug deep to uncover why dirty parts were consistently reaching customers. Their investigation revealed one crystal-clear root cause: Training Gaps in Standard Operating Procedures.

The maintenance technicians weren't fully versed in proper cleaning protocols. Despite good intentions, they lacked comprehensive understanding of the established standards, leading to inconsistent cleaning results. Kure's systematic analysis tools helped the team validate this finding with confidence.

The Solutions

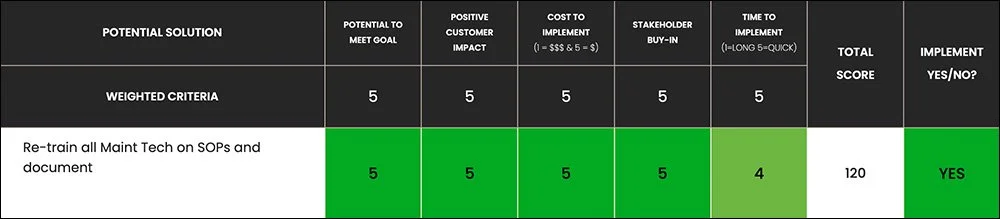

With Kure's guidance providing solution templates and improvement suggestions, the team developed a laser-focused intervention: Comprehensive SOP Training Program.

The company rolled out engaging training sessions that thoroughly covered every cleaning procedure aspect. These hands-on sessions ensured every maintenance technician mastered the Standard Operating Procedures. They also created user-friendly documentation of these procedures, making them instantly accessible during daily work.

Kure's workflow kept the team on track, helping the team create a successful training program that accelerated implementation by weeks.

The Results

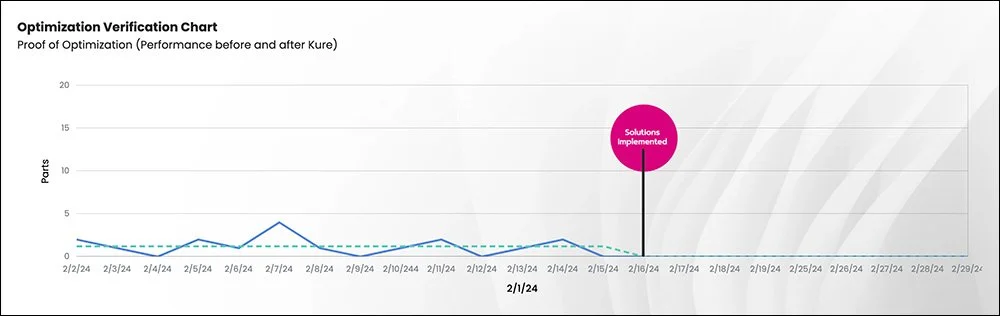

The impact was nothing short of spectacular! After implementing the training program, dirty parts returns vanished completely—dropping from eight monthly returns to zero. This perfect 100% improvement transformed a critical weakness into a notable strength.

The benefits multiplied across the organization:

Zero Dirty Parts Returns: Complete elimination of cleanliness issues restored the company's quality reputation and eliminated costly returns processing.

Delighted Customers: Consistently receiving properly cleaned parts rebuilt customer trust and satisfaction, strengthening valuable business relationships.

Energized Workforce: The maintenance team now works with greater confidence and pride, knowing exactly how to meet quality standards every time.

Streamlined Operations: With standardized procedures firmly in place, the cleaning process now runs more efficiently, reducing wasted time and resources previously spent on rework.

Conclusion

This success story showcases how modern, AI-powered process improvement can transform a serious quality issue into a competitive advantage. By harnessing Kure's intelligent workflow system, the team completed their improvement project in record time—up to three times faster than traditional methods.

The company didn't just fix their immediate quality problem; they positioned themselves for long-term success. Kure's AI-driven process improvement platform provided their team with data and process insights that might have taken months to develop the traditional way. The digital tools and templates accelerated implementation, allowing the team to focus on the actual problem rather than project administration.

By investing in both cutting-edge technology and people development, this manufacturer built a foundation for sustained excellence that will continue driving customer satisfaction and competitive advantage for years to come. Their journey proves that with the right digital tools and improvement methodology, manufacturing quality challenges can be overcome faster and more effectively than ever before.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.