Automotive Manufacturer Reduces Parts Damage By 92% And Saves $780K Per Year With Kure

PROJECT SUMMARY

The problem: At a fast-paced automotive manufacturing plant in Troy, Michigan, an ongoing issue was creating costly headaches: parts were getting damaged during handling and transport. Every day, about 12 parts were scrapped due to in-system damage. This wasn’t just an inconvenience—it was wasting time, money, and resources.

Determined to put an end to this problem, the company turned to Kure, an AI-powered process improvement platform, to guide the team through a structured, step-by-step problem-solving approach. With Kure’s AI-driven workflow, the team was able to dramatically reduce damaged parts and save $780,000 per year.

The Problem

When manufacturing high-quality automotive parts, precision is everything. Damaged parts don’t just add up in costs—they disrupt production, delay orders, and frustrate employees who have to deal with the fallout.

The plant’s leadership team knew this was a critical issue that needed immediate attention. The key challenges included:

Escalating Costs: At $3,000 lost per day from damaged parts, the plant was bleeding $780,000 annually.

Production Delays: Scrapping parts meant missed deadlines and inefficient production schedules.

Employee Frustration: Workers were spending valuable time dealing with damaged inventory instead of focusing on quality production.

The company assembled a dedicated improvement team, led by an experienced project leader. To streamline the problem-solving process, they used Kure’s AI-powered workflow, which follows the DMAIC (Define, Measure, Analyze, Improve, Control) methodology. Kure provided step-by-step guidance, examples, and real-time data analysis, helping the team focus on solving the problem instead of getting stuck in process complexities.

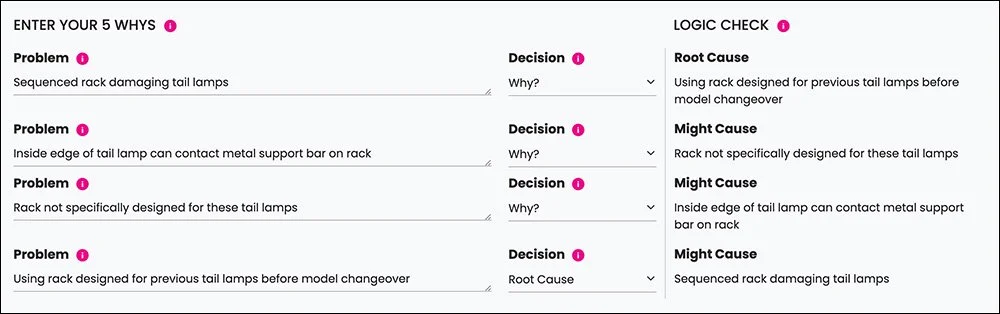

The Root Causes

With Kure’s AI-driven insights, the team quickly identified the root cause: Outdated Part Racks. The plant was using racks designed for a previous vehicle model. These old racks didn’t securely fit the updated parts, leading to damage during transport and handling.

Before using Kure, diagnosing this issue would have taken weeks of trial and error. But with AI-driven data analysis and guided questioning, the team uncovered the problem in record time.

The Solutions

Thanks to Kure’s intelligent workflow, the team developed a practical and cost-effective solution: Modify Part Racks. The team redesigned and adjusted the racks to properly fit the current part design, ensuring a secure and damage-free transport process.

By using Kure’s AI-driven guidance, the team could focus on implementing solutions faster, rather than getting bogged down by paperwork or guesswork.

The Results

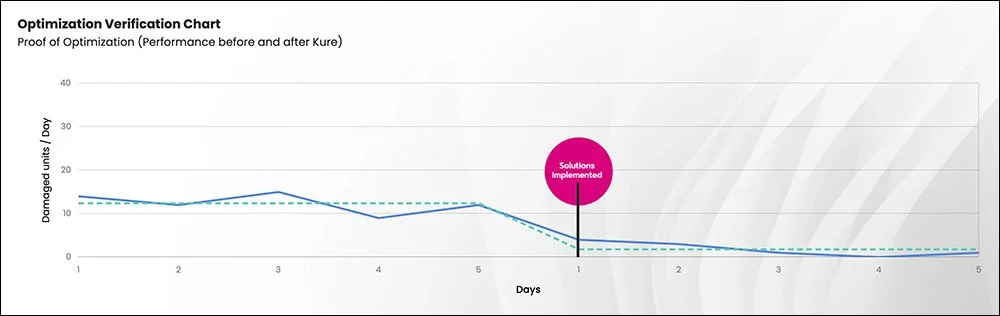

The impact of these changes was immediate and game-changing:

92% Reduction in Scrapped Parts: The number of damaged parts dropped from 12 per day to just 1, eliminating unnecessary waste.

$780,000 in Annual Savings: By reducing damage, the plant stopped losing $3,000 per day, dramatically improving profitability.

Faster, More Efficient Production: With fewer damaged parts, production ran smoothly, avoiding unnecessary slowdowns.

Happier Employees: Workers no longer had to waste time dealing with damaged inventory, boosting morale and job satisfaction.

Conclusion

This project proved that AI-driven process improvement isn’t just the future—it’s the key to solving manufacturing challenges faster and smarter. Kure’s AI-powered workflow helped the team complete the project up to 3 times quicker than traditional methods by offering expert guidance, real-time suggestions, and automated analysis.

By using Kure, the company not only reduced waste and saved money but also positioned itself for future success. This case study is a testament to how Kure empowers teams to take control of their processes, drive continuous improvement, and achieve outstanding results—faster than ever before.

With Kure leading the way, this is just the beginning of what’s possible for the company’s future!

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.