Manufacturer Reduced Order Fulfillment Time By 86% With AI-Driven Kure

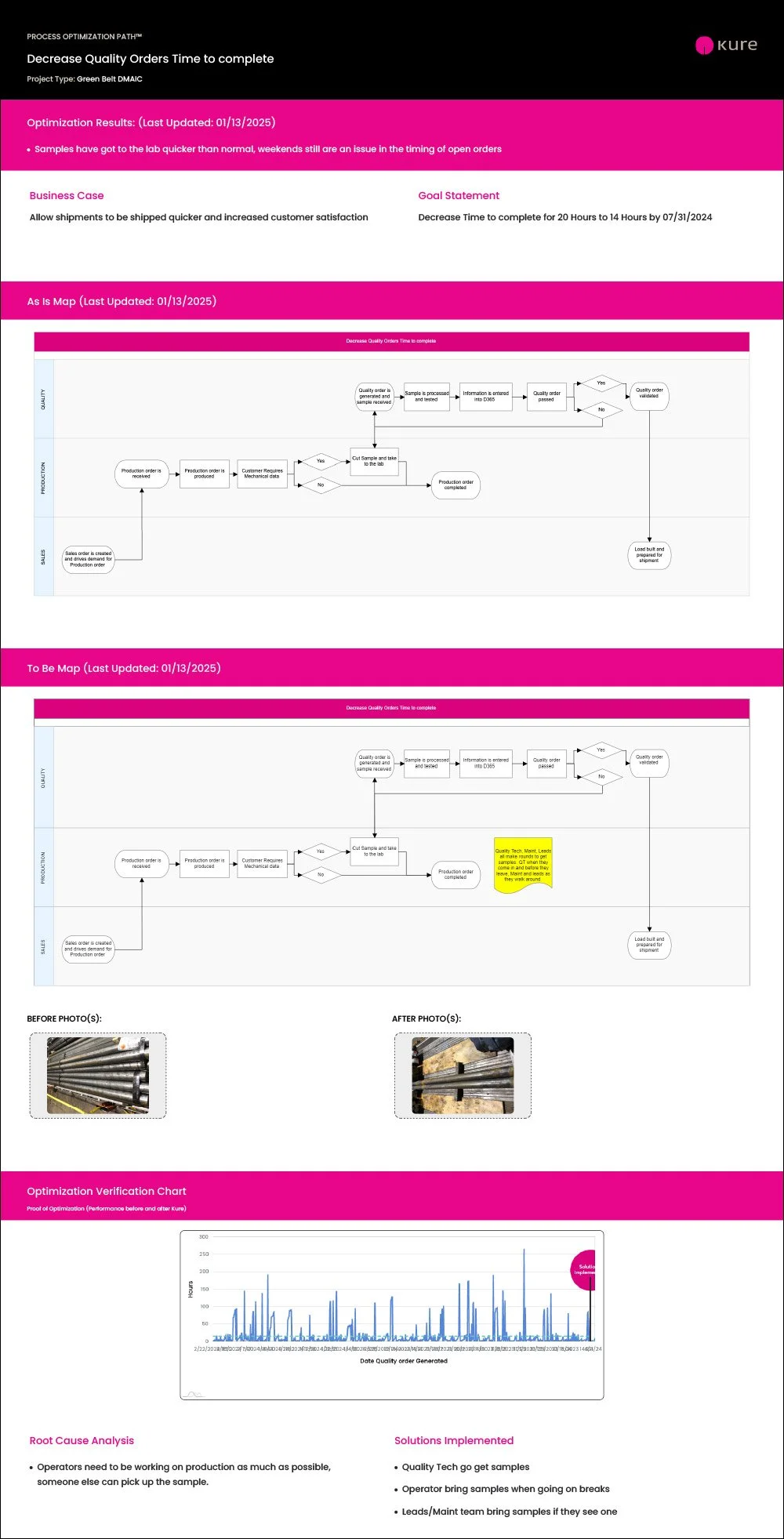

PROJECT SUMMARY

The problem: A steel manufacturer was struggling with significant delays in their order fulfillment process. Orders that should have taken hours were dragging on for up to 200 hours, leaving customers frustrated and the company’s reputation at risk.

Determined to fix this critical issue, the company turned to Kure, an AI-powered process improvement software. Kure’s structured, guided workflow helped the team uncover the root causes of delays, implement effective solutions, and achieve an impressive 86% improvement in order fulfillment time.

The Problem

Efficient order fulfillment is crucial in today’s competitive steel manufacturing industry. For this company, delays in fulfilling orders were threatening their ability to meet customer expectations. On average, it took 15.2 hours to complete an order, and in some cases, it took much longer. These delays not only disappointed customers but also created inefficiencies that drove up costs and hampered productivity.

Determined to address the problem, the organization assembled a dedicated team, including a project leader trained in Lean Six Sigma methodologies, to lead the effort. Using Kure’s AI-powered process improvement software, the team followed the structured DMAIC framework (Define, Measure, Analyze, Improve, Control) to tackle the challenges head-on and focus on solutions that delivered results.

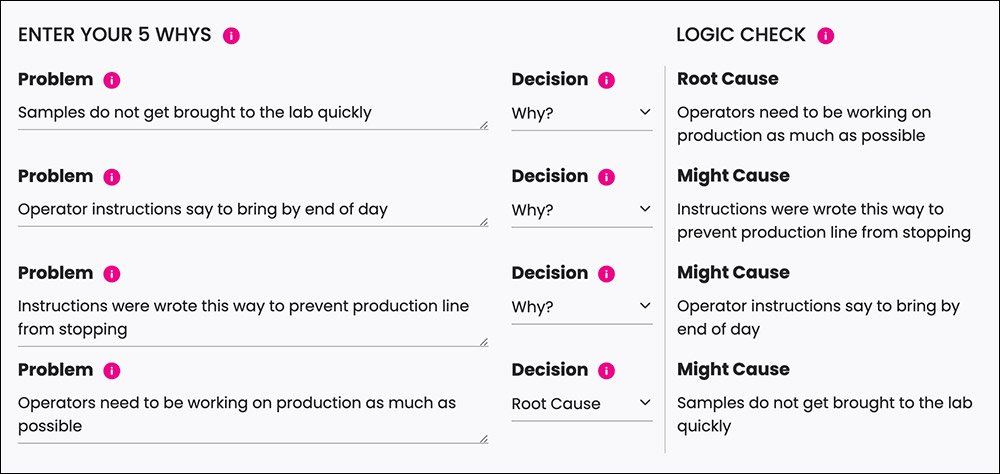

The Root Causes

A deep dive into the process revealed a clear bottleneck: operators were spending too much time collecting product samples for quality testing. This essential task pulled them away from the production line, disrupting workflows and slowing down overall operations.

The team realized that relying on operators for sample collection was inefficient and led to avoidable delays. To streamline the process, they needed a solution that maintained quality control while allowing production to run smoothly.

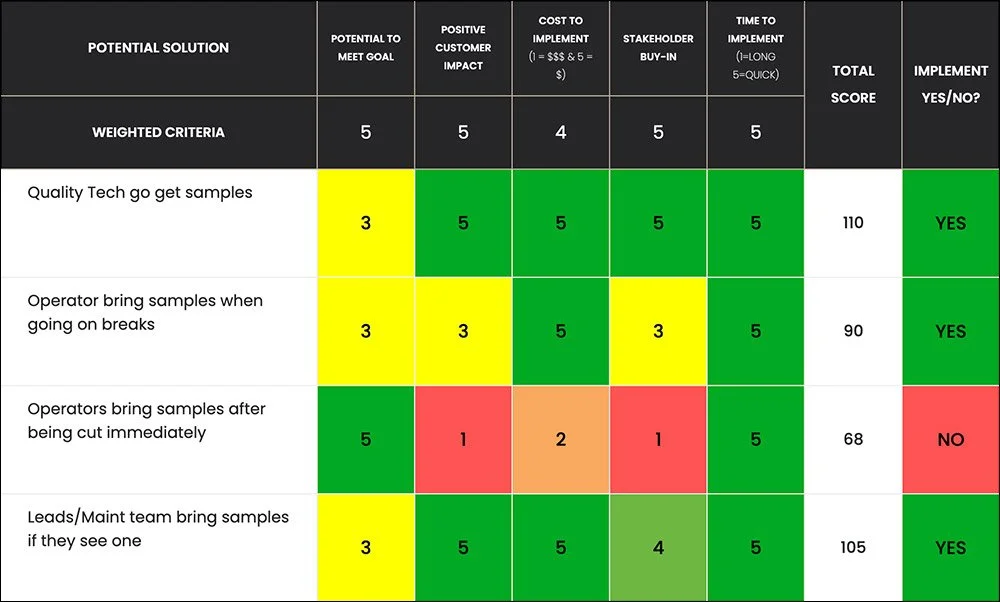

The Solutions

With Kure’s AI-driven guidance, the team identified and implemented three practical solutions:

Reassigning Responsibilities: Sample collection was assigned to Quality Technicians, freeing up operators to focus on production tasks.

Adding Flexibility: Operators were given the option to deliver samples during their scheduled breaks if Quality Technicians were unavailable. This minimized disruptions to production.

Empowering Other Roles: Team leads and maintenance staff were trained to handle sample delivery when necessary, ensuring continuous workflow without bottlenecks.

Kure’s intuitive workflow provided clear examples, expert suggestions, and real-time data analysis, enabling the team to make decisions quickly and confidently.

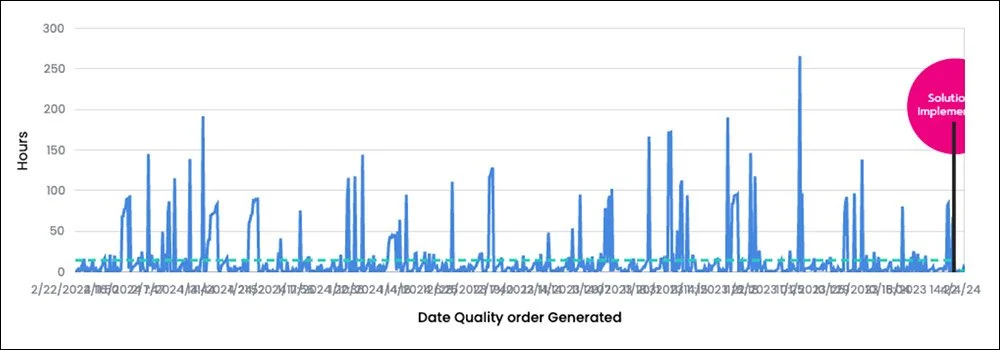

The Results

The improvements were immediate and substantial:

Order Fulfillment Time Slashed: The average order fulfillment time dropped from 15.2 hours to just 2.2 hours—an 86% improvement.

Increased Efficiency: By keeping operators focused on production, the company reduced labor costs and increased operational efficiency.

Happier Customers: Faster fulfillment times delighted customers, boosting satisfaction and strengthening trust in the company.

Before & After

Although the team is continuing to fine-tune processes for weekend shifts, the overall transformation has set a new standard for efficiency and customer service.

Conclusion

This project showcases the remarkable impact of Kure’s AI-powered process improvement software. By guiding the team through the DMAIC process with tailored insights, clear instructions, and actionable recommendations, Kure enabled the organization to achieve results up to three times faster than traditional methods.

Thanks to Kure, the company is now better equipped to meet demand, satisfy customers, and tackle future challenges with confidence. This success story highlights the value of leveraging AI-driven tools to drive meaningful, lasting improvements that position businesses for long-term success.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.