Food Manufacturer Reduced Package Weight Variation By 44% And Unlocked $757K In Annual Savings With Kure

PROJECT SUMMARY

The problem: The premium nuggets product—representing 27% of total production—was experiencing significant product giveaway due to inconsistent bag weights, non-standard machine settings, and lack of standardized responses, making variation reduction critical to protecting margins and reducing waste at scale.

By implementing standardized bagger-level data tracking and more frequent weight checks, the team reduced average bag weight variation from 36 grams to 20 grams (44% reduction), improved yield by 4–5%, and positioned the operation to recover 526,000 pounds annually—equivalent to approximately $757,000 in savings and a 2% yield gain.

The Problem

A leading food manufacturer—family-owned for four generations—operates more than 20 facilities across the Southeast and employs over 7,500 team members. What began as a small hatchery and feed mill has grown into a globally respected supplier known for quality and customer satisfaction.

In food processing, small variations can create big financial consequences. When products are slightly overweight, the company gives away value. When they’re underweight, quality and compliance are at risk. With high production volumes and tight margins, reducing variation is essential.

To address this challenge, the organization selected GLSS Training & Certification to build internal improvement capability and leveraged Kure to guide project execution and track progress in real time. The team embraced Ethical Efficiency™—focusing not only on financial gains, but also on protecting product integrity, supporting frontline employees, and creating sustainable, repeatable improvements.

Led by Project Team Lead Cesar Escobar Lobo, the team launched the Package Weight Variation Reduction project to strengthen control, reduce giveaway, and improve yield on one of their highest-volume products.

Their premium nuggets product accounts for 27% of total plant production, with 25.8 million pounds expected in 2025. On two primary lines, packout yield averaged 165%, signaling significant product giveaway caused by variation in bag weights and inconsistent subline performance.

Machine settings were not standardized. Responses to weight variation differed by shift. Even when data showed drift, adjustments were not always made quickly or consistently.

For a product produced at this scale, even small overfills added up to major financial loss. Without better control, the organization risked continued waste, shrinking margins, and inconsistent performance. Process improvement was critical to protecting profitability and long-term competitiveness.

The Root Causes

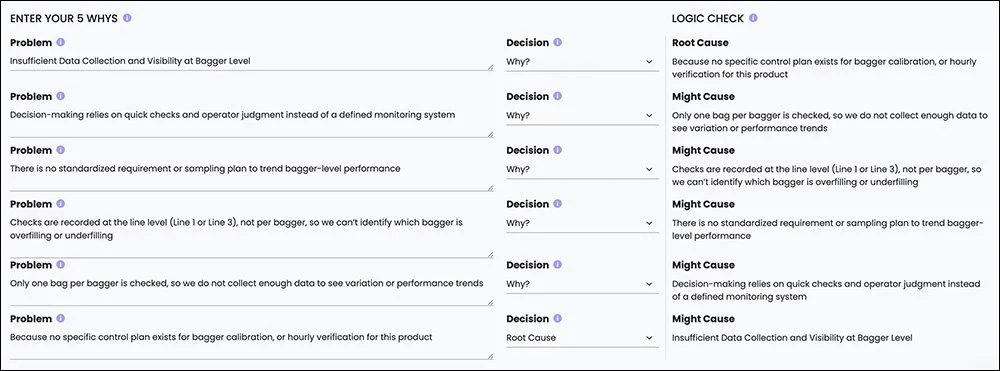

Using Kure’s structured framework, the team mapped the process, analyzed performance data, and identified the true drivers of variation.

First, there was no defined control plan for bagger calibration and hourly verification. Without consistent checks, weights gradually drifted.

Second, there was no clear reaction plan when piece-weight data trended up or down. Teams could see the numbers—but did not have a standardized response.

Third, there was no shift-independent control plan. Each shift handled issues differently, leading to inconsistent adjustments and continued giveaway.

These gaps made variation predictable—but preventable.

The Solutions

Through Kure, the team implemented practical, focused solutions. They introduced bagger-level data visibility so operators and supervisors could monitor performance by machine and quickly identify variation.

They increased the frequency and accuracy of 10-piece weight checks in the breading process. More frequent verification meant earlier detection—and faster corrective action. They also clarified standard work and reaction plans across shifts, ensuring consistent responses whenever variation appeared.

By improving coordination between breading and packout teams, they strengthened in-process control and reinforced accountability.

The Results

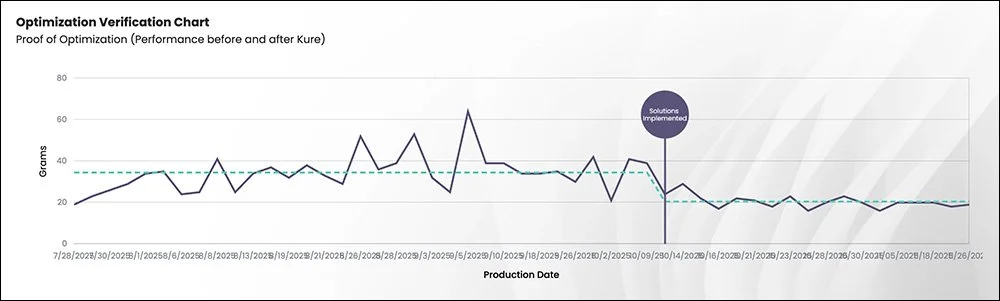

The improvements delivered fast, measurable impact.

Average bag weight variation decreased from 36 grams to 20 grams, a 44% reduction in variation. Yield improved by 4–5%, demonstrating immediate financial benefit.

The operation is now positioned to recover an estimated 526,000 pounds annually, equivalent to approximately $757,000 in savings and a 2% yield gain for the product line.

Beyond the numbers, standardized checks are now consistently applied across shifts. Communication between teams has improved. Adjustments happen faster, and control is more reliable.

Conclusion

By combining internal capability with Kure’s structured, easy-to-follow execution platform, this food manufacturer achieved meaningful results quickly—and built a strong foundation for sustained success.

Kure helped the team move from analysis to action faster, keeping the project organized and ensuring solutions were documented and sustained. Ethical Efficiency™ guided every step—reducing waste while protecting product quality and supporting the people doing the work.

This project did more than reduce variation. It strengthened discipline, improved collaboration, and created a repeatable framework for future improvements.

With measurable results and a scalable system in place, the organization is well positioned to continue driving operational excellence—one data-driven improvement at a time.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.