Manufacturer Increased Box on Demand Throughput By 38% With Kure

PROJECT SUMMARY

The problem: A critical packaging operation was limiting outbound flow, driving overtime, delivery pressure, and rising labor costs across the organization.

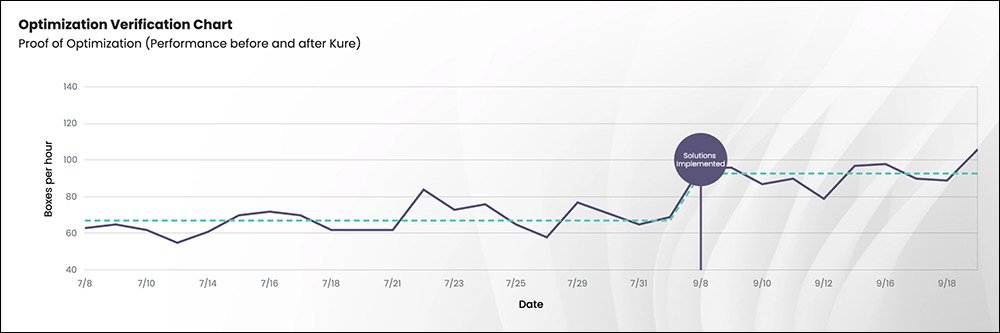

By improving training, equipment reliability, and workflow stability, the team increased throughput from 67 boxes per hour to an average of 92.8 boxes per hour—a 38% improvement that significantly reduced the bottleneck.

The Problem

Manufacturing organizations face constant pressure to increase throughput, control labor costs, and meet demanding delivery schedules. When a single operation becomes a bottleneck, the effects can quickly spread across the entire value stream. To address this challenge efficiently, the organization chose Kure to manage its Box on Demand Throughput Increase project.

Kure’s structured workflow and automated documentation allowed the team to move from problem identification to execution with speed and clarity. At the same time, the organization leveraged GLSS Training & Certification to build the problem-solving skills needed to identify root causes and implement solutions through an Ethical Efficiency™ lens, improving performance while supporting people and long-term sustainability.

Low production output from the Box on Demand machine had become a significant constraint in the outbound operation. The process was averaging 67 boxes per hour, limiting throughput and creating downstream delays. To keep up with demand, teams relied on overtime and workarounds, driving up labor costs and placing added strain on employees. Delivery performance also suffered as schedules became harder to maintain. Improving throughput at this critical step was essential to restoring flow, stabilizing labor, and protecting customer commitments—making process improvement a business necessity, not an option.

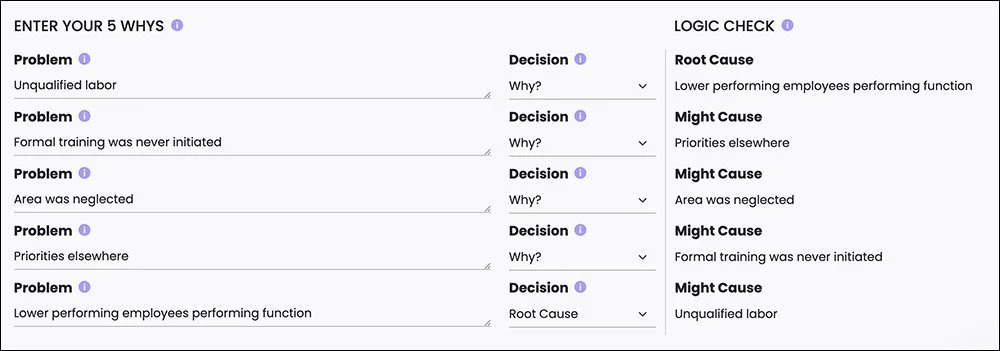

The Root Causes

One root cause was inconsistent operator capability. Employees assigned to the Box on Demand role had widely varying skill levels, and there was no standardized training or qualification process to ensure consistent performance across shifts.

A second root cause stemmed from a leadership transition. As expectations shifted, focus on training discipline, equipment care, and accountability became inconsistent. This led to variability in machine performance and increased downtime, further limiting throughput.

The Solutions

The first solution was the development of standardized training for the Box on Demand role, along with the creation of a qualified operator roster. This ensured that only trained and capable employees were assigned to operate the machine. Operator-Driven Reliability (ODR) was also added to the role, giving operators clear ownership of daily performance checks and basic maintenance tasks.

The team also implemented a preventive maintenance (PM) schedule. By proactively addressing equipment issues before they caused breakdowns, unplanned downtime was reduced and machine reliability improved.

Finally, additional product lines were introduced to increase available work-in-process (WIP). This helped keep the Box on Demand machines running consistently and reduced idle time caused by product availability gaps.

The Results

Managing the project in Kure allowed the team to track actions, timelines, and outcomes in one centralized location, significantly shortening the project lifecycle. Automated documentation reduced manual reporting and kept the team focused on execution and results.

Throughput increased from an average of 67 boxes per hour to 92.8 boxes per hour, representing a 38% improvement. The Box on Demand operation was no longer a major bottleneck, overtime was reduced, delivery performance improved, and labor costs stabilized. Just as importantly, clear standards and operator ownership improved confidence, engagement, and consistency on the shop floor.

Conclusion

By using Kure to manage the improvement effort, the organization achieved results faster while automatically capturing insights and lessons learned. Paired with GLSS Training & Certification’s innovative instructional design and practical, real-world focus, the team delivered meaningful improvements with less administrative burden. Guided by Ethical Efficiency™, the project balanced performance gains with respect for people—positioning the organization for future success with a repeatable, scalable approach to continuous improvement and operational excellence.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.