Manufacturer Improved On-Time Completion By 157% With Kure

PROJECT SUMMARY

The problem: The deburr process was constantly missing its on-time delivery targets. The company was spending up to $10,128 per week in overtime, and this wasn’t just draining the budget—it was burning out the team.

With Kure, this manufacturer improved their on-time completion rate from 35% to 90%—a 157% improvement.

The Problem

In manufacturing, timing is everything. If one step falls behind, it can throw off the entire production line—causing late shipments, unhappy customers, and rising costs. That’s exactly what one manufacturer was experiencing with their deburr process, a vital step that was consistently slowing things down.

To tackle the issue head-on and get real results, the company turned to Kure, an AI-powered digital improvement platform. Kure helps teams move faster with guided problem-solving, automatic documentation, and built-in collaboration tools. Even better, the team used Kure to apply the principles of Ethical Efficiency™, making improvements that benefited both the business and the people doing the work.

The deburr process had become a major bottleneck. Parts weren’t being completed on time, which delayed orders and created a backlog for the entire production line. To keep up, six employees were working 60 hours of overtime per week, costing the company $10,128 every week in extra labor.

Beyond the financial hit, the heavy workload was putting strain on the team. The organization needed a better way forward—one that didn’t rely on burnout to meet customer demand. It was clear that process improvement was not just important—it was essential.

The Root Causes

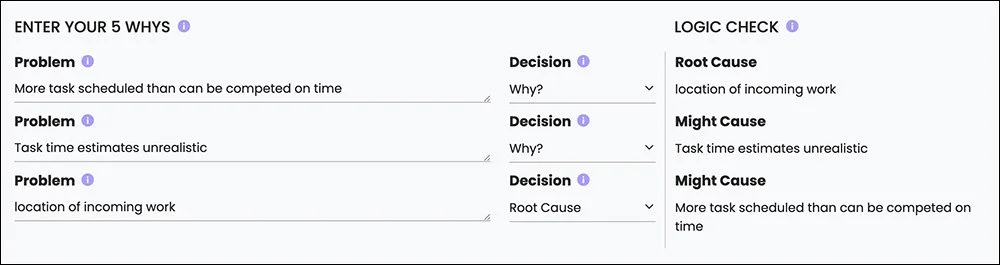

Thanks to Kure’s step-by-step DMAIC framework (Define, Measure, Analyze, Improve, Control), the team quickly zeroed in on the root causes:

Poor layout: Incoming work was placed too far from where operators were working, creating a lot of unnecessary walking and wasted motion.

Split scheduling: The scheduler had to manage two different deburr areas that were doing the same type of work, making the workflow harder to organize and predict.

With Kure’s AI-driven insights and built-in analysis tools, the team was able to visualize the inefficiencies and align on the changes needed—without relying on spreadsheets or manually piecing everything together.

The Solutions

Using Kure to guide the improvement journey, the team put several key solutions into action:

Centralized supplies: All necessary tools and materials were organized in one shared location, making it easier for operators to work efficiently.

Combined work areas: The two deburr zones were consolidated into a single space, simplifying scheduling and reducing confusion.

Moved incoming shelves: By placing shelves closer to the operator, they eliminated excess movement and saved valuable time.

Planned ahead: The scheduler began assigning jobs in advance, giving the team a clearer daily workflow.

Throughout the project, Kure automatically tracked every step, documented progress, and kept the entire team connected and focused. No extra apps, no extra work—just clear progress, faster.

The Results

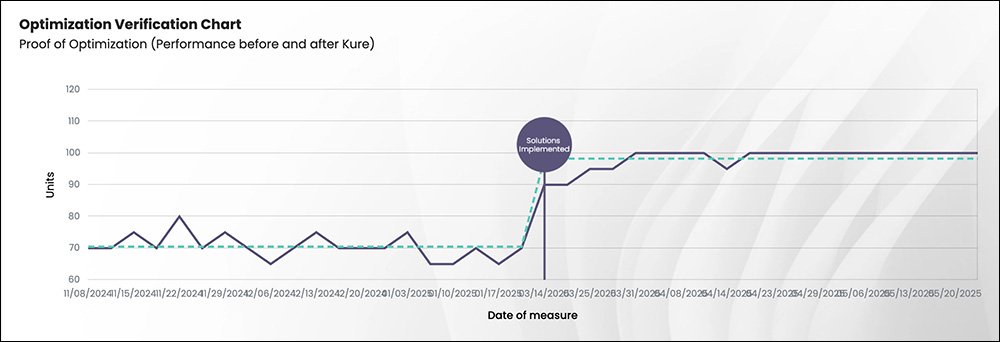

The improvements made a huge impact. The team increased their on-time completion rate from 35% to 90%—a 157% improvement that helped the company meet customer deadlines and operate more smoothly.

At the same time, unplanned overtime was cut by 28%, reducing costs and giving employees a much-needed break from extra hours. Thanks to Kure’s built-in documentation and data tracking, the team was able to show results clearly and sustain the gains well beyond the end of the project.

Conclusion

Choosing Kure helped this manufacturing team solve a complex challenge with speed and confidence. Instead of struggling with messy tools or unclear next steps, they followed a guided path that helped them focus on solutions—and get results faster.

By following the principles of Ethical Efficiency, they didn’t just fix a process—they made it better for everyone involved. The deburr process is now streamlined, costs are lower, and the team is less stressed and more productive.

This project proves that when improvement is people-first and platform-powered, big results don’t have to come with big headaches. With Kure, the future is not just more efficient—it’s more sustainable, too.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.