Reducing Part Washer Electricity Consumption By 82% With Kure

PROJECT SUMMARY

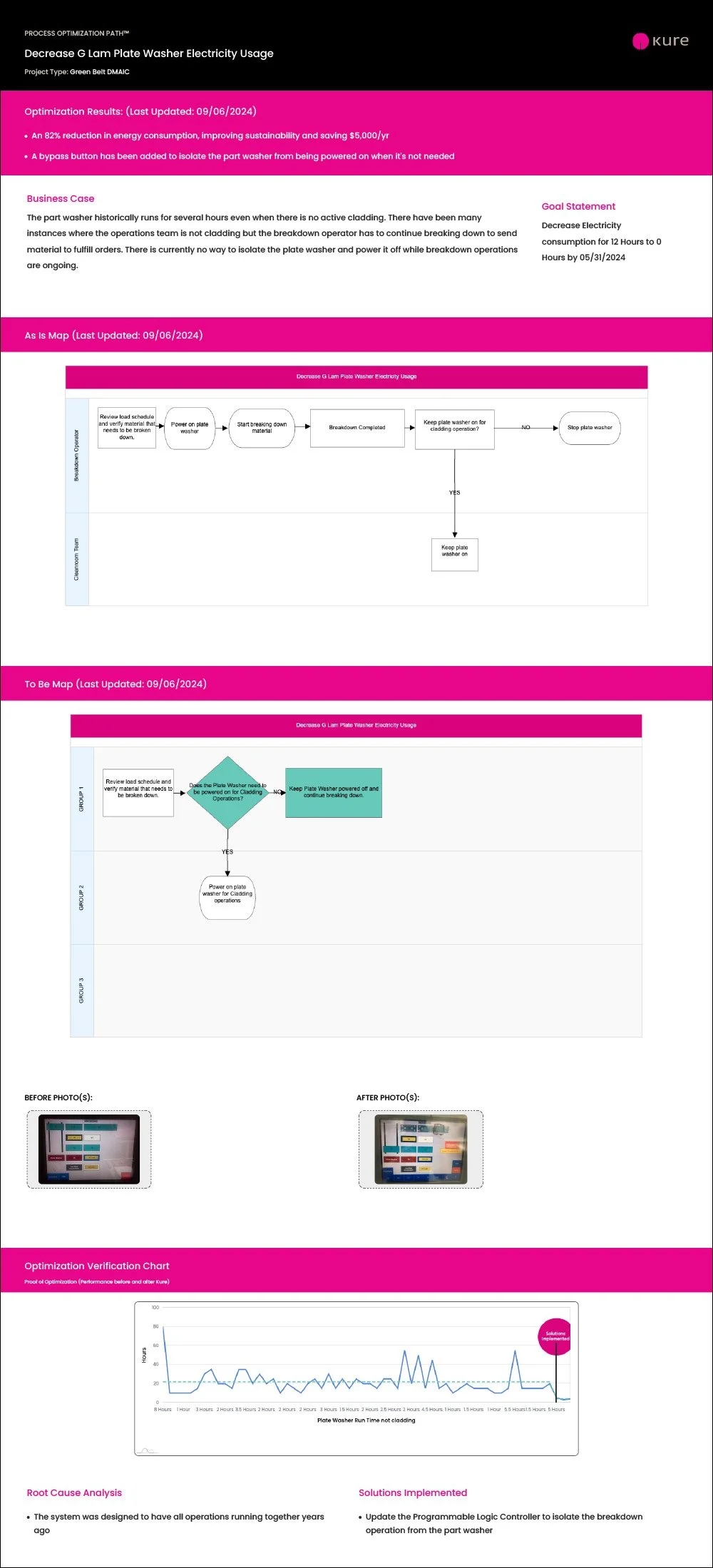

Business Case

The part washer historically runs for several hours even when there is no active cladding. There have been many instances where the operations team is not cladding but the breakdown operator has to continue breaking down to send material to fulfill orders. There is currently no way to isolate the plate washer and power it off while breakdown operations are ongoing.

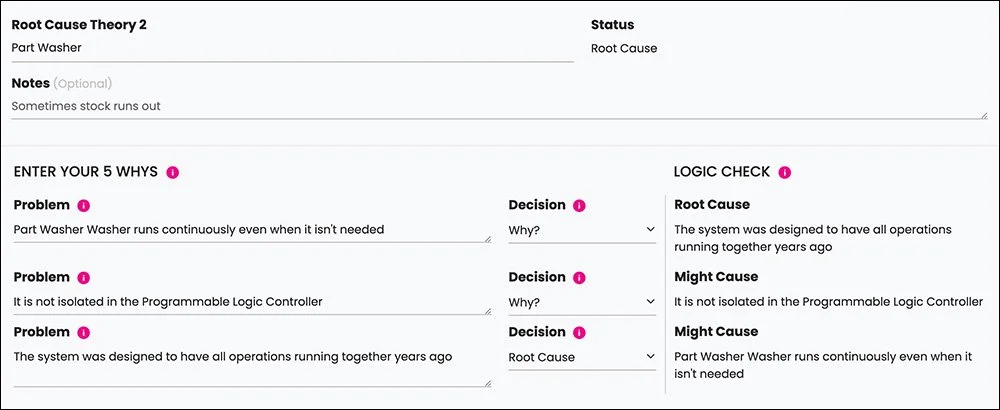

Root Cause Analysis

The system was designed to have all operations running together years ago

Solutions Implemented

Update the Programmable Logic Controller to isolate the breakdown operation from the part washer

Project Results

An 82% reduction in energy consumption, improving sustainability and saving $5,000/yr

A bypass button has been added to isolate the part washer from being powered on when it’s not needed

Summary

The problem: A manufacturing facility sought to address the excessive energy consumption of its part washer system. This project aimed to reduce operational inefficiencies and meet sustainability goals by optimizing the washer's electricity usage.

By utilizing Kure, the organization was able to reduce energy waste by 82% while enhancing operational control.

The Problem

In manufacturing, efficiency and sustainability are key to staying competitive. At this facility, the part washer was designed to run nonstop whenever production was active—even when washing wasn't needed. This led to skyrocketing energy bills, unnecessary equipment wear, and a bigger carbon footprint.

Operators couldn't shut down the washer without halting production equipment, making the system both inflexible and wasteful. Recognizing the need for change, the company knew that improving this process was essential for cutting costs and supporting their sustainability goals.

They assembled a team of dedicated professionals, led by a project leader pursuing GLSS Lean Six Sigma Green Belt Training & Certification. The team turned to Kure, an AI-driven process improvement software that follows the DMAIC (Define, Measure, Analyze, Improve, Control) methodology. With Kure's helpful examples, guidance, suggestions, and AI data analysis, they streamlined their project work, allowing them to focus on solving the problem and complete the project up to three times faster.

The Root Causes

Digging deep into the issue, the team discovered that the real culprit was the limitations of the existing programmable logic controller (PLC). The PLC didn't allow the part washer to operate separately from the production line, so it ran continuously, wasting energy when it wasn't needed. Plus, operators didn't have the tools to intervene, which added to the energy waste.

The Solutions

Armed with insights and Kure's guidance, the team implemented two key solutions:

Updating the PLC: They reprogrammed the PLC so the washer could operate independently. Now, operators could shut it down whenever washing wasn't required, saving energy right away.

Installing a Manual Bypass Switch: They added a manual switch, giving operators direct control over the washer. Conveniently placed, this switch allowed for easy shutdown without disrupting production.

Using Kure's AI-driven workflow, the team efficiently followed the DMAIC methodology. Kure's support helped them identify the necessary PLC changes and streamline the entire process.

The Results

The impact was immediate and remarkable. The washer's operating hours plummeted from 22 hours to just 4 hours per day, leading to an 82% reduction in electricity consumption. This not only slashed costs but also aligned perfectly with the company's sustainability initiatives by reducing its carbon footprint.

Conclusion

This success story showcases how Kure's innovative AI-powered platform can drive quick and effective results. By updating the PLC and adding a bypass switch, the facility not only solved its energy consumption problem but also set itself up for future success. Kure enabled the team to complete the project faster than traditional methods, and now they have the skills to maintain these improvements. The company is enjoying ongoing operational excellence and sustainability, laying a strong foundation for continued growth and efficiency.

*We value our clients’ confidentiality. While we’ve changed their names, the results are real.